Products

Overview

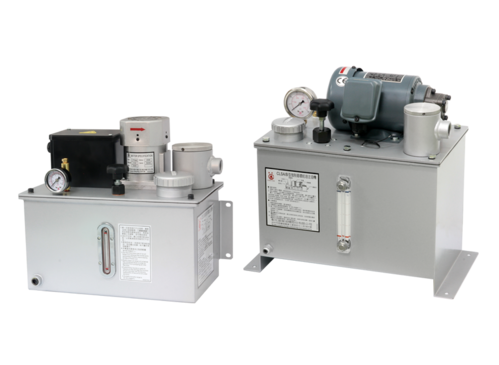

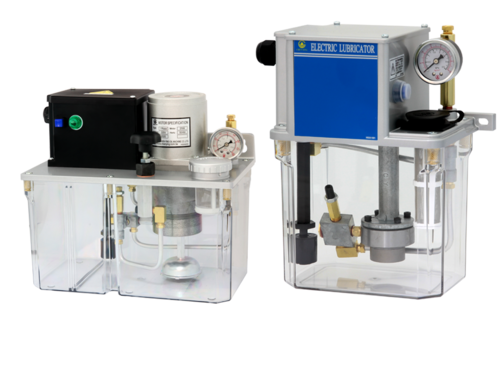

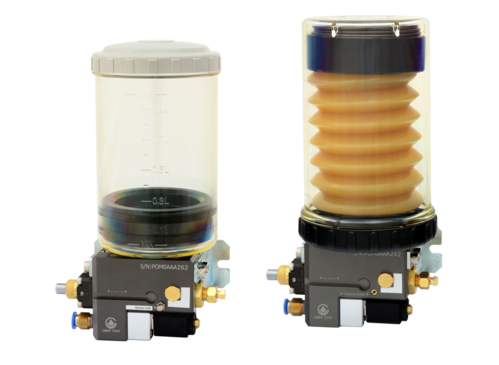

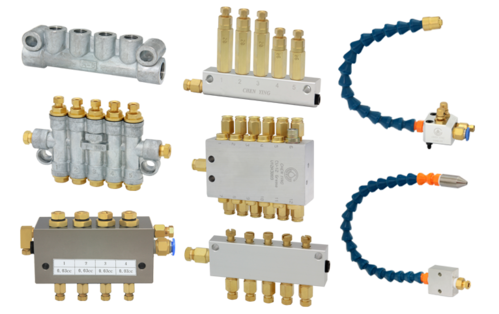

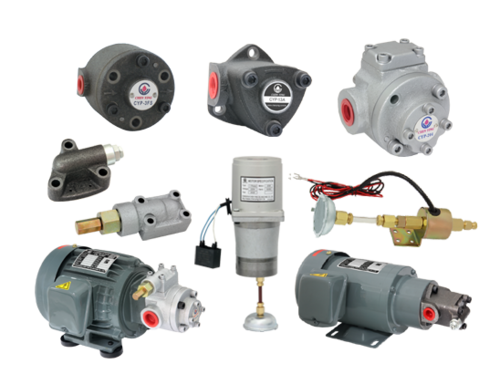

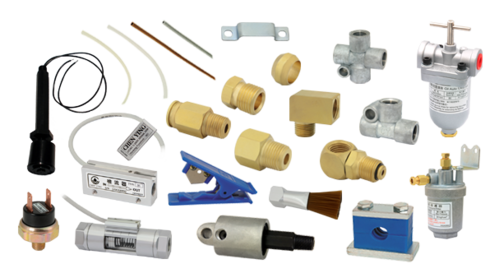

Centralized lubrication systems are designed to efficiently deliver precise and consistent lubrication to industrial machinery. By supplying the correct volume of lubricant to every lubrication point, Centralized lubrication systems effectively reduce friction, prevent bearing seal damage, and ensure reliable machine operation. A typical centralized lubrication system consists of a central pump and reservoir, controller, and a network of pipes with metering valves to precisely deliver the correct amount of oil to each point while the equipment is running. This system is used to increase efficiency, reduce wear, minimize downtime, lower maintenance costs, and improve equipment lifespan.

The types of Centralized Lubrication Systems offered by Chen Ying include:

Key Advantages of Centralized Lubrication System

Easy Installation and Flexible Operation

Our centralized lubrication systems can be operated manually or automatically, ensuring the right lubrication frequency even under demanding working conditions. This improves maintenance efficiency while reducing errors.Reduce Friction & Enhance Operating Efficiency

By accurately delivering lubricants with adjustable timing and flow control, the system maintains an optimal lubrication film on bearings, gears, and linear guides. This results in lower internal resistance, reduced wear, and improved mechanical performance — ultimately increasing production uptime and profitability.Extend Machinery Life

Consistent lubrication reduces friction, prevents overheating, and prolongs the lifespan of critical machine components, improving overall reliability and uptime.Wide Industrial Application

Centralized lubrication systems are widely used across industries that rely on high-precision and high-duty machinery, including:

| Industrial Applications | Descriptions |

| CNC machines | Centralized lubrication system ensures critical components are properly protected from wear and heat generation during continuous operation. |

| Milling machines, lathes, and drilling machines | Industrial machine tools depend on centralized lubrication system to deliver controlled lubrication to spindles, gearboxes, slides, and linear guideways. This prevents metal-to-metal contact, reduces downtime, and significantly extends the overall service life of the machine. |

| Punching and stamping machines | Automated oil-spray lubrication is used to reduce die wear, cool tooling during high-speed forming and protect the work piece surface from damage. |

| Conveying and automated production equipment | Automated lubrication system supports multiple lubrication points throughout conveyors and manufacturing equipment. This minimizes manual maintenance and maintains continuous high-efficiency production. |

| Construction machinery | Automatic lubrication system is essential to ensure uninterrupted duty cycles, reduce mechanical stress, and prolong component durability under heavy workloads. |

| Manufacturing Equipment & Industrial Machinery | Across automated production lines, centralized lubrication system enables stable machine performance, lowers maintenance requirements, and ensures consistent operation. |

Related links

What is “Centralized Lubrication System”?

Why do Machines Require Lubrication?

Differences between Resistance Type and Pressure-Relief Type Lubrication Systems

How to Choose the Right Lubrication System for Your CNC Machine?

How to Choose the Right Automatic Lubrication System?