8.How to Choose the Right Automatic Lubrication System

Comprehensive Guide to Lubrication Systems:

Enhancing Machinery Performance and Reliability

An automatic lubrication system, also known as a centralized lubrication system, delivers lubricant to moving machine parts while the equipment is running. These systems help prevent breakdowns and keep equipment operating efficiently. Studies show that around 70% of equipment failures in factories are caused by poor lubrication. Automatic lubrication systems reduce wear, extend machine life, and help avoid costly repairs. They are widely used in industries such as manufacturing and mining to improve machine reliability and reduce maintenance costs.

Key Takeaways

- Automatic lubrication systems supply the correct amount of lubricant to machine parts during operation, helping to prevent damage and costly failures.

- These systems save money by reducing downtime, lowering repair costs, and increasing machine lifespan.

- Key components—such as pumps, controllers, and metering devices—work together to ensure lubrication is delivered at the right time and in the right quantity.

- Different types of lubrication systems are available for various machines. Selecting the right system improves performance and reliability.

- Choosing the appropriate lubricant—whether grease or oil—depends on machine requirements and operating conditions. The right choice ensures safety and optimal performance.

Related links

Why do Machines Require Lubrication?

Differences between Oil and Grease Lubrication Systems

Automatic Grease Lubrication System: Equipment, Applications, and Solutions

Benefits of Automatic Lubrication System

Extended Equipment Lifespan

Machines are built to perform over the long term, and automatic lubrication systems play a key role in ensuring that longevity. By delivering the precise amount of lubricant at the right time, these systems reduce excessive wear and prevent premature part failure. Improper lubrication—whether too much or too little—is a leading cause of equipment breakdowns. Automatic systems eliminate this risk by providing consistent and accurate lubrication.

Many companies have reported noticeable improvements in equipment reliability and lifespan. With fewer unplanned stoppages and reduced repair time, overall productivity improves.

Reduced Maintenance Costs

Automatic lubrication systems are designed to optimize maintenance routines and reduce overall operational costs. By minimizing the need for manual lubrication, these systems help reduce labor hours, lower the frequency of emergency repairs, and improve overall machine uptime.

In many industries, companies have reported improvements such as:

- Increased machine availability

- Reduced planned and unplanned maintenance

- Lower repair costs and spare part usage

- Improved worker safety by eliminating high-risk lubrication tasks

Improved Efficiency

Automatic lubrication improve machine performance by delivering lubricant while the equipment is running—no need to stop operations. This reduces downtime and increases overall productivity. Unlike manual lubrication, which can be inconsistent or excessive, automatic systems ensure the right amount is applied precisely where it’s needed. This not only reduces lubricant consumption but also enhances safety by minimizing worker exposure to hazardous areas. Over time, these improvements lead to smoother operations and greater output.

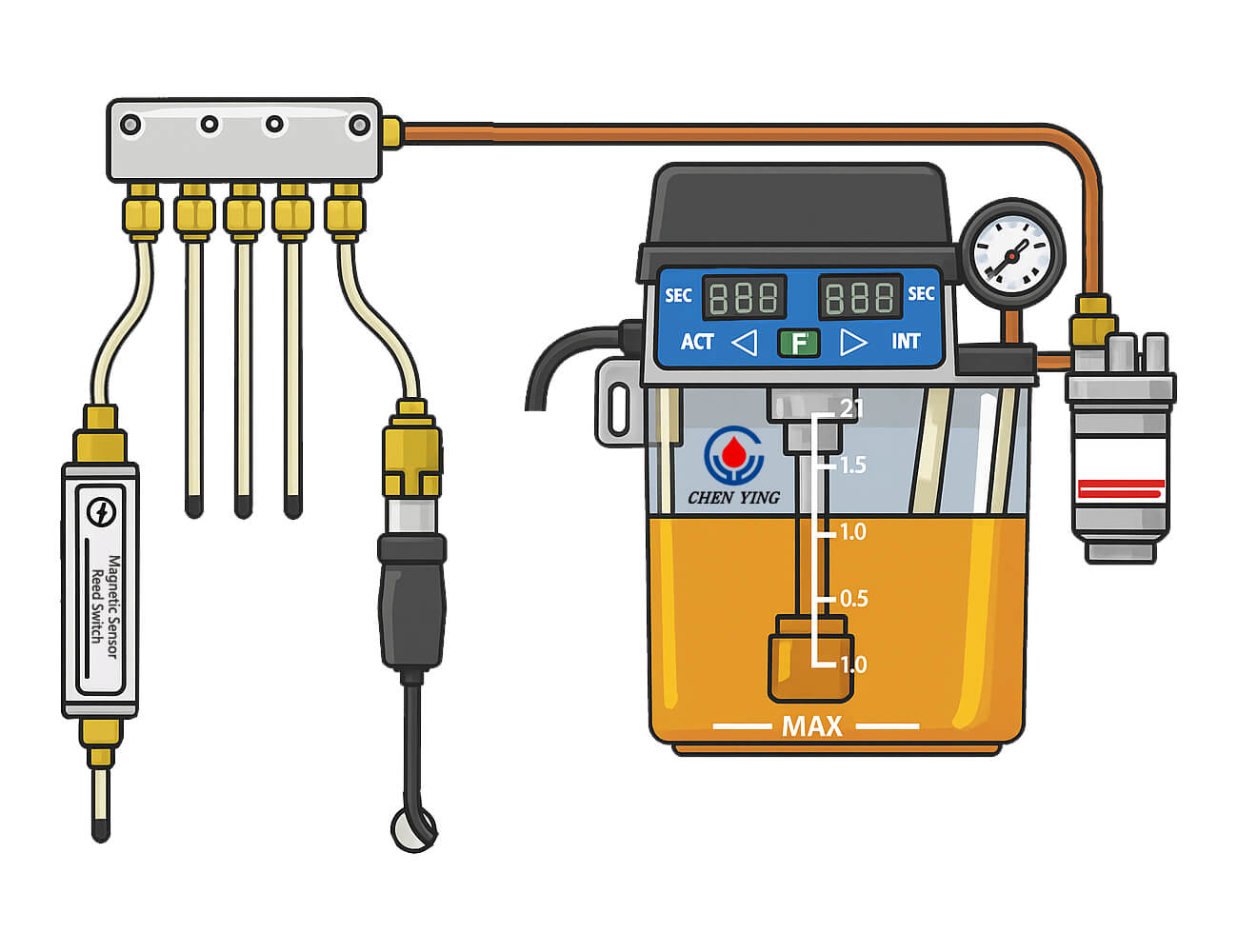

Lubrication System Components

Automatic lubrication systems consist of several essential components, each with a specific function. Understanding how these parts work together helps you better manage and maintain your equipment.

| Component | Function |

| Pump | Moves lubricant through the system by creating pressure. |

| Motor | Powers the pump for steady operation. |

| Distributor | Directs lubricant to the right places. |

| Reservoir | Holds the lubricant until it is needed. |

| Metering Device | Measures and controls how much lubricant goes to each point. |

| Controller | Sets the timing and amount of lubricant delivered. |

| Tubing & Fittings | Carry lubricant from the reservoir to the machine parts. |

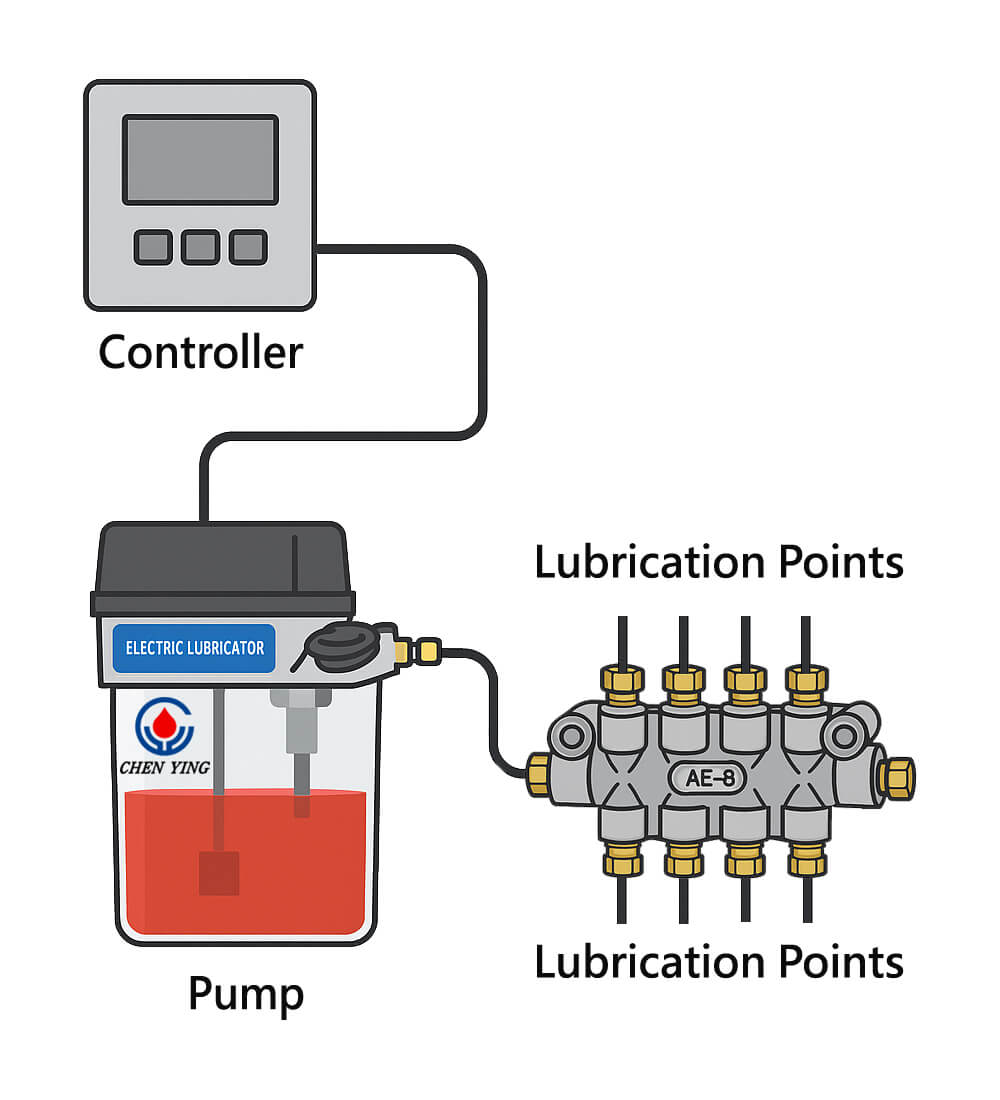

Pump

The pump moves lubricant from the reservoir into the system by generating pressure. It ensures that grease or oil reaches every lubrication point. A high-quality pump with secure connections prevents leaks and maintains consistent operation.

Motor

The motor powers the pump, allowing it to run at the proper speed. A durable, efficient motor ensures reliable lubrication even under demanding conditions.

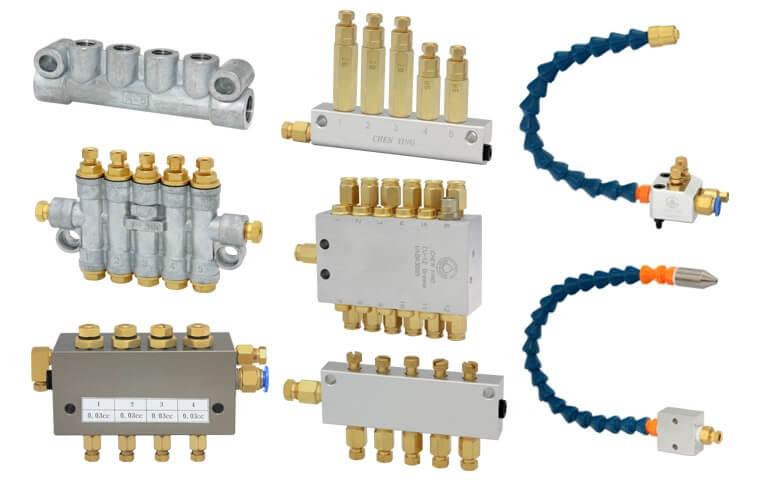

Distributor

The distributor divides the lubricant flow and directs it to various lubrication points. It ensures each component receives the correct amount of lubricant.

Reservoir

The reservoir stores grease or oil until needed. Many include level sensors that alert users when lubricant is low, helping to prevent dry running or unexpected system failures.

Metering Device/Volumetric Distributor

A metering device controls how much lubricant each point receives, using valves or injectors for precision. Some models feature visual indicators or electrical switches for blockage detection.

Controller (Timer)

The controller (Timer) acts as the system's brain. It schedules lubrication based on machine operation and usage requirements, helping prevent human error and improving timing accuracy.

Tubing and Fittings

Tubing and fittings transport lubricant from the reservoir to each lubrication point. Quality tubing resists leaks and clogs, ensuring long-term system performance.

How the System Works

Lubricant

Delivery

Automatic lubrication systems deliver precise amounts of lubricant directly to moving components while the equipment remains in operation, eliminating the need for downtime. A pump transfers grease or oil from the reservoir into the distribution network. The lubricant flows through tubing and fittings to targeted lubrication points, ensuring each location receives the exact quantity required. A controller, functioning as the system’s central processing unit, governs pump activation and shut-off cycles. Metering devices and valves regulate and measure the lubricant flow, preventing both under-lubrication—which accelerates wear—and over-lubrication, which can cause heat buildup and contamination. Tip: An automatic system ensures consistent coverage, including hard-to-access or hazardous points, improving safety and reliability.

Operation Cycle

The system operates in a programmed sequence, referred to as a lubrication cycle, which dispenses lubricant at predefined intervals, in precise quantities, and in a specific order. This process minimizes friction, extends bearing life, and reduces component wear.

- Lubricant is dispensed to the correct points at the optimal time.

- Each cycle is based on the set-point, set-amount, and set-order principle.

- Parameters for timing and volume can be customized to match the application.

- The system can serve a single machine or multiple machines simultaneously.

- Integrated safety features, such as pressure alarms and fault indicators, enhance reliability and ease of maintenance.

Types of lubrication cycles:

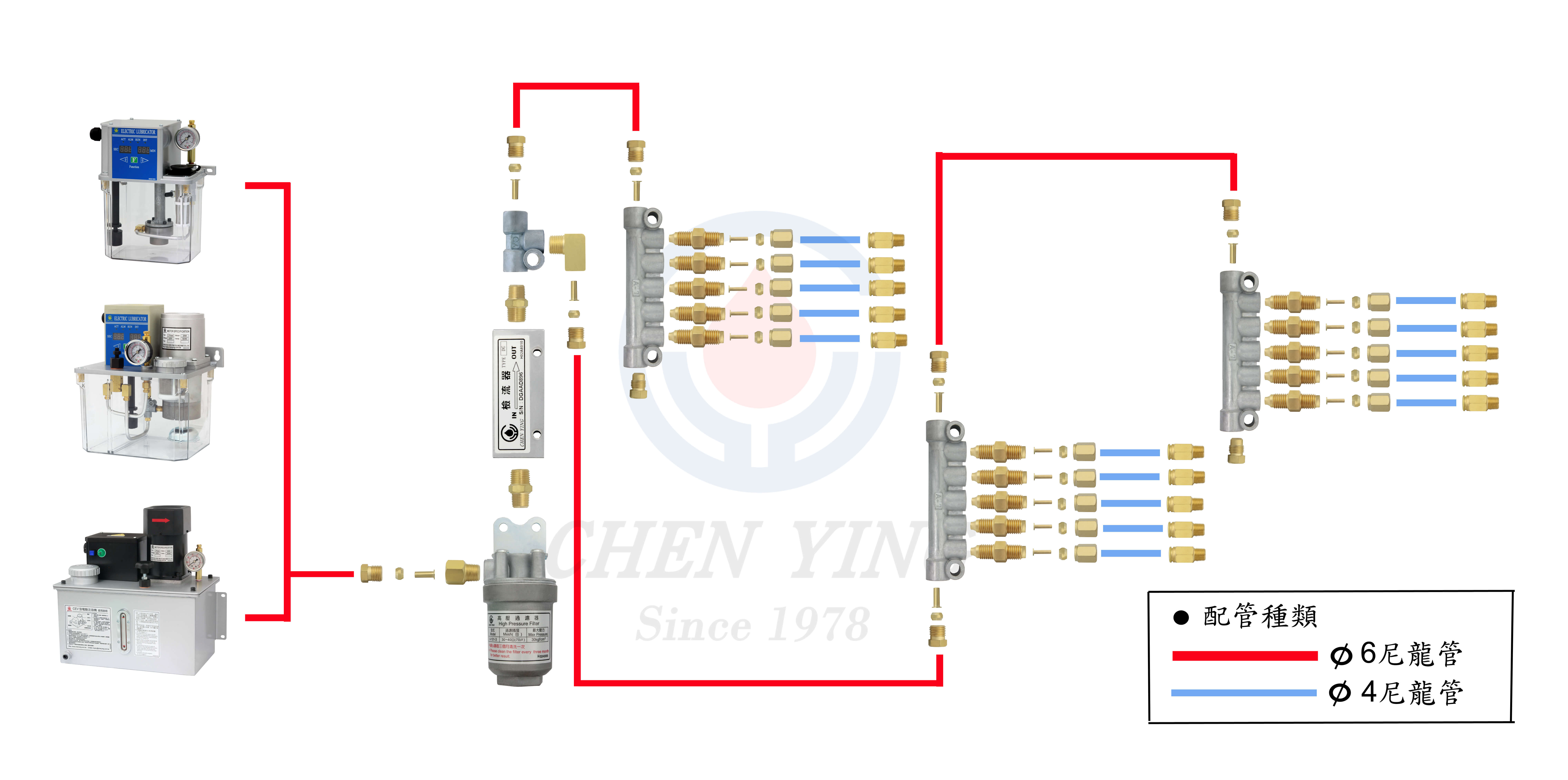

Different automatic lubrication systems use different cycling methods to deliver lubricant. Choosing the right type depends on the number of lubrication points, the distance between them, the lubricant type, and your machine’s operating conditions.

- Progressive Systems – Deliver lubricant to one point at a time in a fixed sequence. Each point receives its dose before the next point is served. Ideal for small to medium-sized machines with closely grouped lubrication points.

- Pressure-Relief Type PDI Systems – Each inject delivers a precise, measured volume when the system reaches operating pressure. After delivery, a pressure-relief valve vents the main line, resetting all injectors simultaneously for the next cycle. This ensures consistent dosing across all lubrication points, even in large-scale or complex systems with long feed lines. Designed for use with our automatic lubrication pumps and controllers, this configuration is highly reliable and easy to maintain.

- Dual-Line Systems – Alternate lubricant flow between two main lines. One line feeds a set of lubrication points while the other resets, allowing the system to handle hundreds of points over long distances.

Selecting the Right Cycle

Your choice of lubrication cycle should match your equipment’s needs and operating environment. Our engineering team can help you determine the optimal system and cycle settings to ensure reliable, efficient lubrication for maximum equipment life.

Monitoring

A well-designed lubrication system should incorporate real-time monitoring to ensure consistent, reliable performance and to enable proactive maintenance. Continuous monitoring provides immediate visibility into lubricant delivery, system health, and fault conditions so that issues can be diagnosed and corrected before they cause equipment damage or unplanned downtime. Modern systems typically integrate sensors, controllers, and operator interfaces to provide layered diagnostics and alarm handling. Key monitoring elements include:

| Monitoring Method | What It Does | Where You Find It |

| Visual indicators | Show lubricant movement with pins or markers | Divider valves, injectors |

| Proximity switches | Detect movement and signal faults | Pump controllers |

| Flow meters/switches | Measure and confirm lubricant flow | Oil-circulation, progressive units |

| Low-level switches | Alert when reservoir lubricant is low | Pump reservoirs |

| Control panels | Display system status and allow parameter changes | System interface |

Note: Proactive monitoring identifies potential faults—such as clogs, low lubricant levels, or flow interruptions—before they escalate into costly failures or downtime.

Types of Lubrication Systems

Different applications demand different lubrication methods. Selecting the correct system ensures optimum performance, extended component life, and reduced operating costs. Our product range includes the following system types:

1. Resistance Type Lubrication Systems

Resistance-type systems deliver lubricant to multiple points through a network of calibrated restrictors or orifices. The flow rate to each point is determined by the resistance in each line. Typical applications: Light-to-medium duty machinery with moderate operating speeds. Advantages: Simple design, low cost, minimal maintenance. Suitable Distributors: Manifold Blocks(also known as Manifold Distributors) and Progressive Feeders. Considerations: Less suitable for high-pressure or variable-load applications.

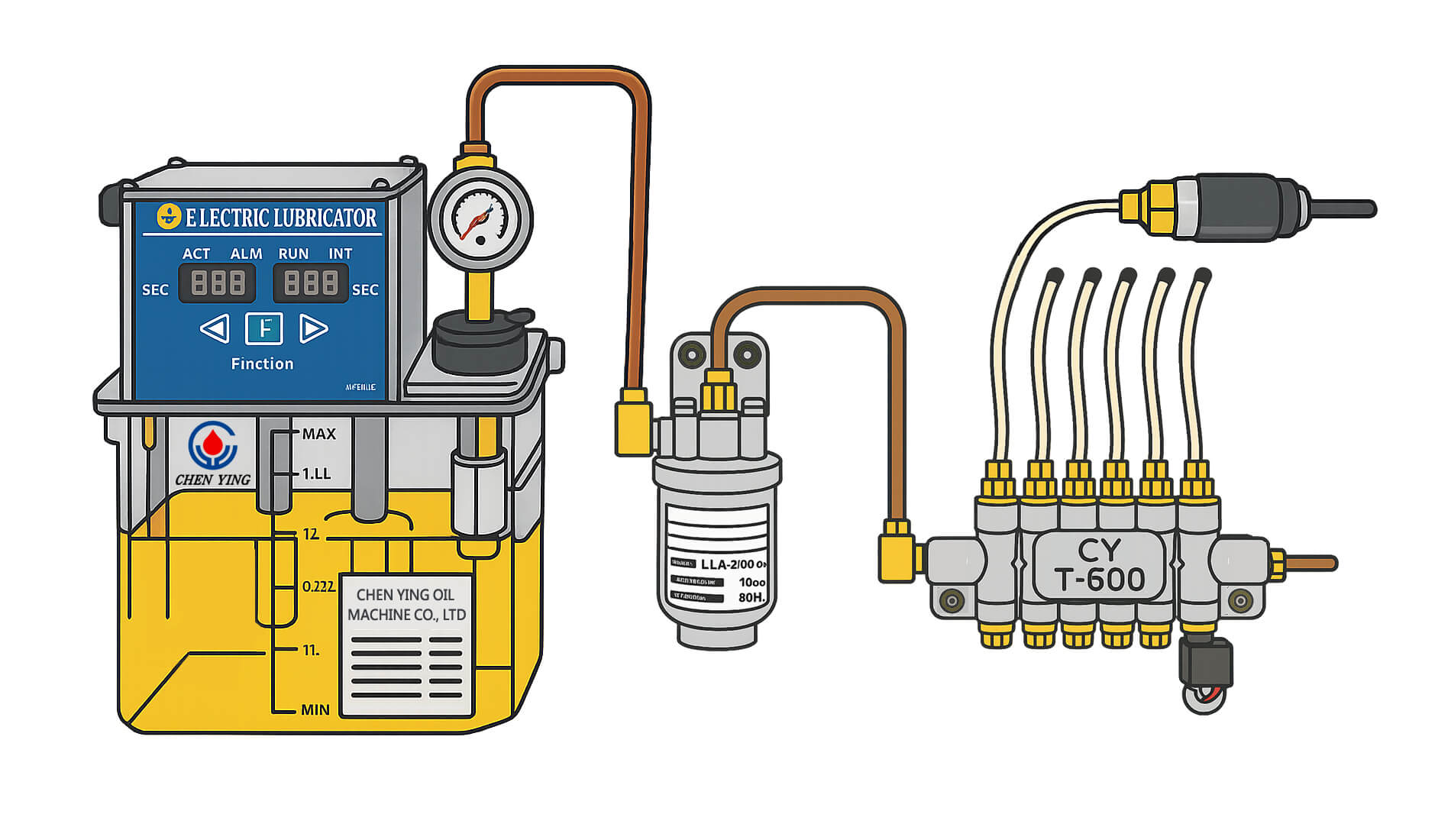

2. Pressure-Relief Type Lubrication Systems

In pressure-relief systems, lubricant is metered to each lubrication point by injectors or metering units that operate under pressure. A pressure-relief valve ensures precise volume delivery and prevents over-lubrication. Typical applications: Heavy-duty equipment, multi-point lubrication on conveyors, presses, and processing machines. Suitable Distributors: Volumetric distributors Advantages: Accurate delivery, suitable for high-viscosity lubricants, reliable under demanding conditions.

Learn more about Pressure-Relief Systems

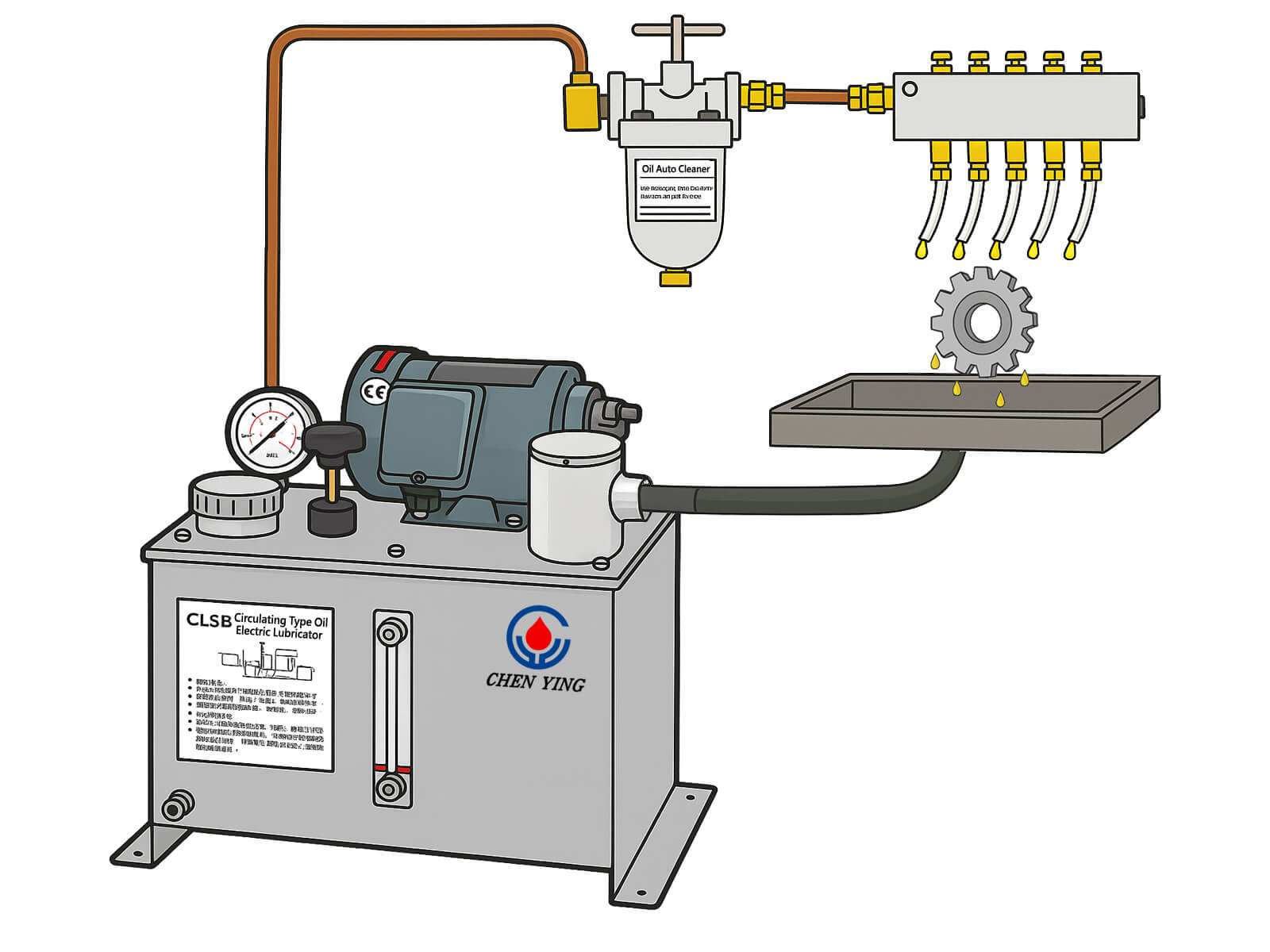

3. Circulating Lubrication Systems

-

Circulating systems continuously deliver filtered lubricant to bearings and other components, then return it to a reservoir for recirculation. Flow and temperature are carefully controlled.

Typical applications: High-speed bearings, gearboxes, turbines, and rolling mills.

Suitable Distributors: Manifold Blocks(also known as Manifold Distributors), BS Distributor

Advantages: Continuous lubrication and cooling, contaminant removal, extended service life. Learn more about Circulating Systems

4. Oil-Mist Lubrication Systems

-

Oil-mist systems atomize lubricant into fine particles, which are carried by air to lubrication points. The mist condenses on surfaces, forming a lubricating film.

Typical applications: Rotating equipment such as pumps, motors, and compressors in petrochemical plants.

Suitable Distributors: OT / OE/ OB Spray Gun

Advantages: Minimal lubricant waste, effective for remote or enclosed components, reduced contamination. Learn more about Oil-Mist Systems

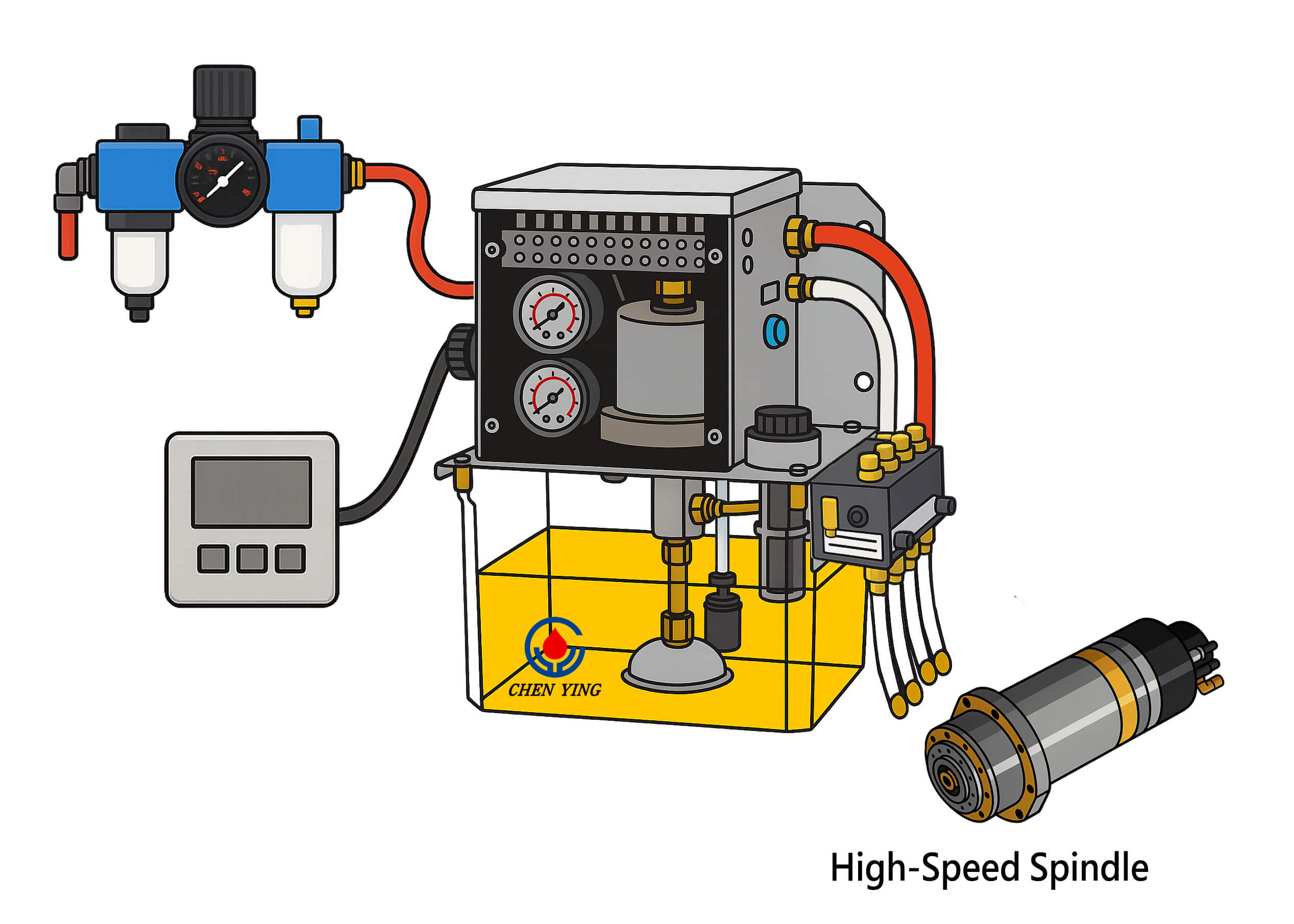

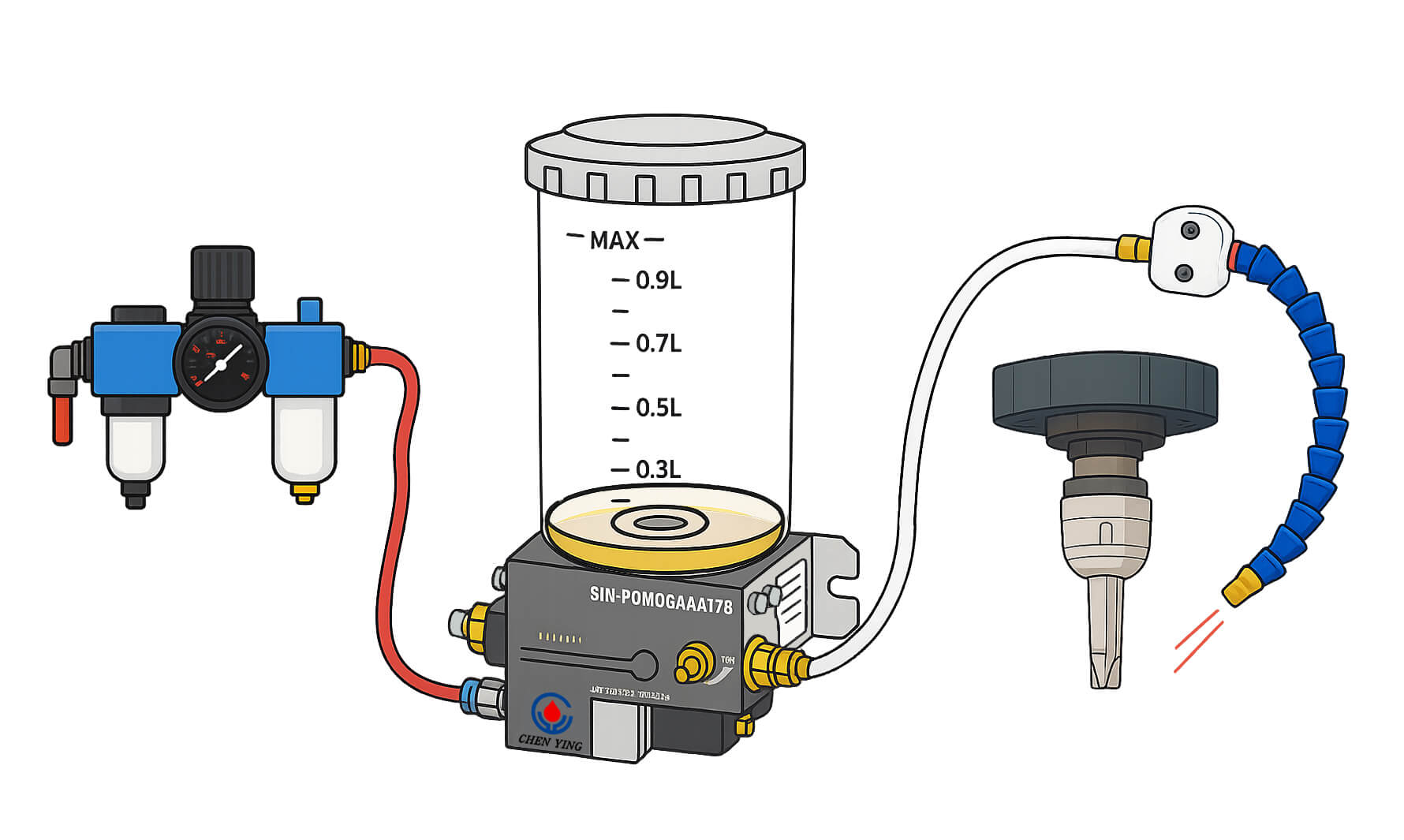

5. Oil-Air Lubrication Systems

-

Oil-air systems deliver small, precisely metered quantities of lubricant mixed with compressed air. The mixture reaches high-speed bearings and critical components with minimal drag and heat buildup. Typical applications: Spindles, high-speed machining centers, rolling mills. Suitable Distributors: OT / OQ Spray Gun, CO, OA, OC Volumetric Distributors Advantages: Reduced frictional heating, excellent for high RPM, clean operation. Learn more about Oil-Air Systems

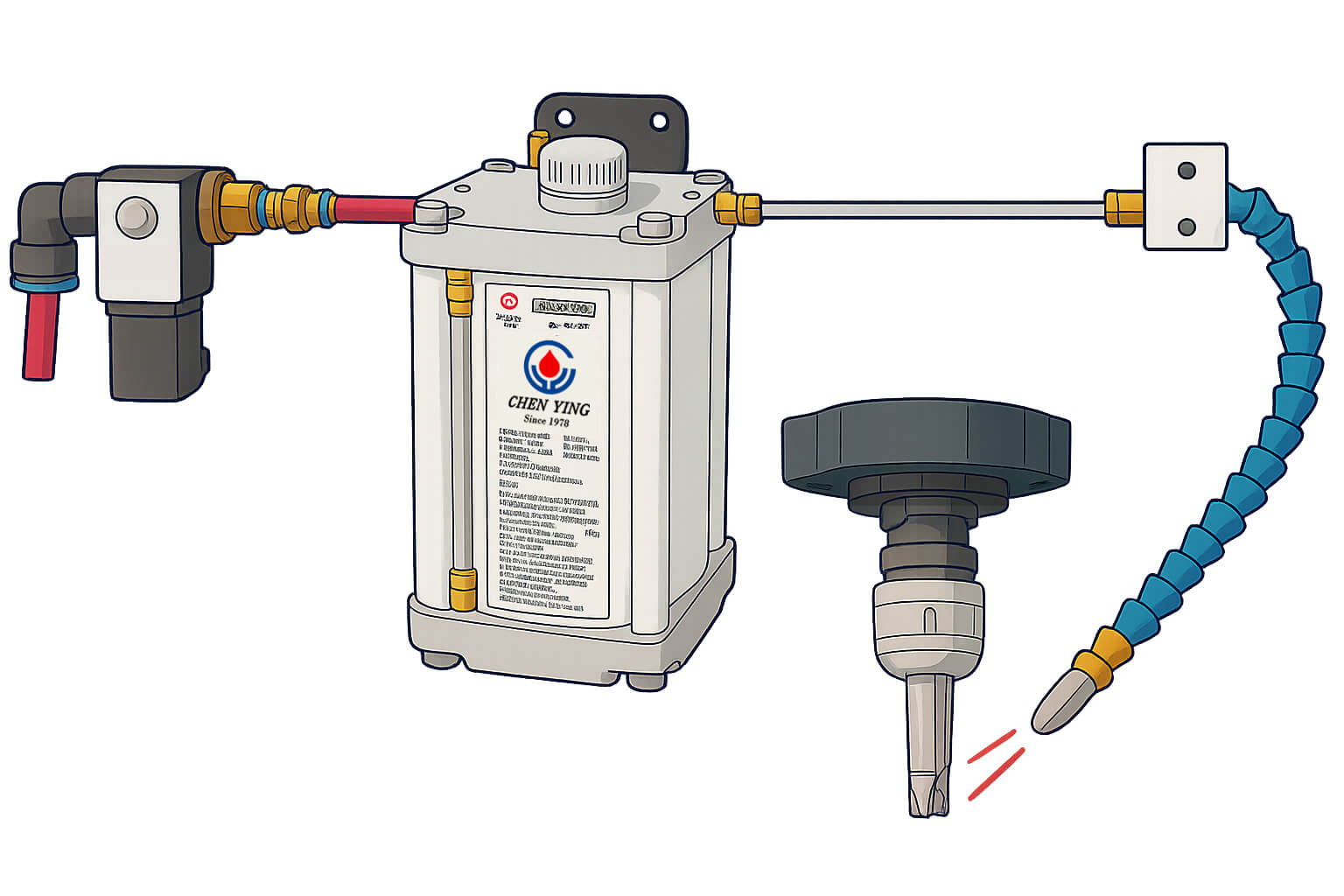

6. Minimum Quantity Lubrication (MQL) Systems

-

MQL systems deliver a very small, exact quantity of lubricant directly to the cutting zone or bearing surfaces. This method is widely used in modern machining to replace flood cooling.

Typical applications: CNC machining, sawing, drilling, and forming operations.

Suitable Distributors: OT / OQ/ OE Spray Gun

Advantages: Drastically reduced lubricant consumption, cleaner work environment, improved tool life. Learn more about Minimum Quantity Oil Systems

Related links

How to Choose the Right Lubrication System for Your CNC Machine?

How to calculate the volume of lubricant for each lubrication point?

Oil Mist Lubrication Systems | Precision, Efficiency & Reliability Chen Ying Oil Machine Co., Ltd.

Circulation Oil Lubrication Systems:Enhancing Efficiency and Reliability in Industrial Applications

FAQ

How often should you check your automatic lubrication system?

Check your system at least once a month. Look for leaks, low lubricant levels, or blocked lines. Regular inspections help you detect issues early and keep your machines running smoothly.

Can you use any lubricant in an automatic system?

No. Always use the lubricant type recommended by your machine’s manufacturer. Using the wrong lubricant can cause clogs or damage. Refer to your manual before adding new grease or oil.

What happens if the system stops working?

If the system stops, your machine parts may not receive enough lubrication, leading to wear or damage. Watch for warning lights or alarms, and address problems immediately to avoid costly repairs.

Is it hard to install an automatic lubrication system?

Most systems are straightforward to install with the right tools. However, some machines may require professional setup. Always follow the manufacturer’s instructions, and seek help if you are unsure.

Do automatic lubrication systems save money?

Yes. These systems reduce lubricant consumption, lower repair costs, extend machine life, and decrease maintenance time. Over time, they deliver substantial savings.