5.Why do Machines Require Lubrication?

Why do Machines Require Lubrication?

When the machine operates at high speed, which generates friction, and friction creates heat, which wears out the parts' surface, reducing precision. Therefore, machinery lubrication is not only necessary, but it is also vital for keeping the machines running functionally.

Components of Industrial Lubrication System

The main components of an industrial lubrication system include a lubricator (or called oil injector, or oil pump), distributors, pipes, fittings, and accessories. Sometimes pressure and level switches are added to complete an enhanced lubrication system.

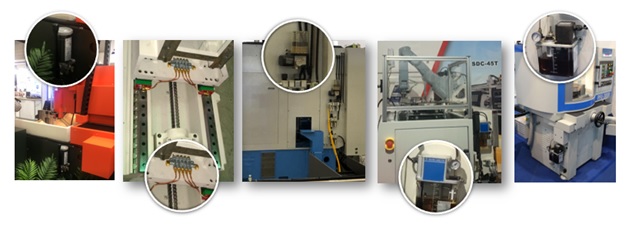

Applications of Industrial Lubrication System

Industrial lubrication systems widely apply to CNC machines, such as stamping presses, milling, grinding, EDM, injection molding, knitting, and weaving machines. The system also can lubricate transmission components, such as bearings, gears, ball screws, and linear guides.In addition to industrial manufacturing, lubrication systems can prevent wear and extend service life for Vehicles, escalator chains, and everything with metal-on-metal contact.