4.How to calculate the volume of lubricant for each lubrication point?

How to calculate the volume of lubricant for each lubrication point?

Various factors determine the amount of lubricant required for each lubrication point in a system, including the specific lubricant needs of the machinery or components serviced.

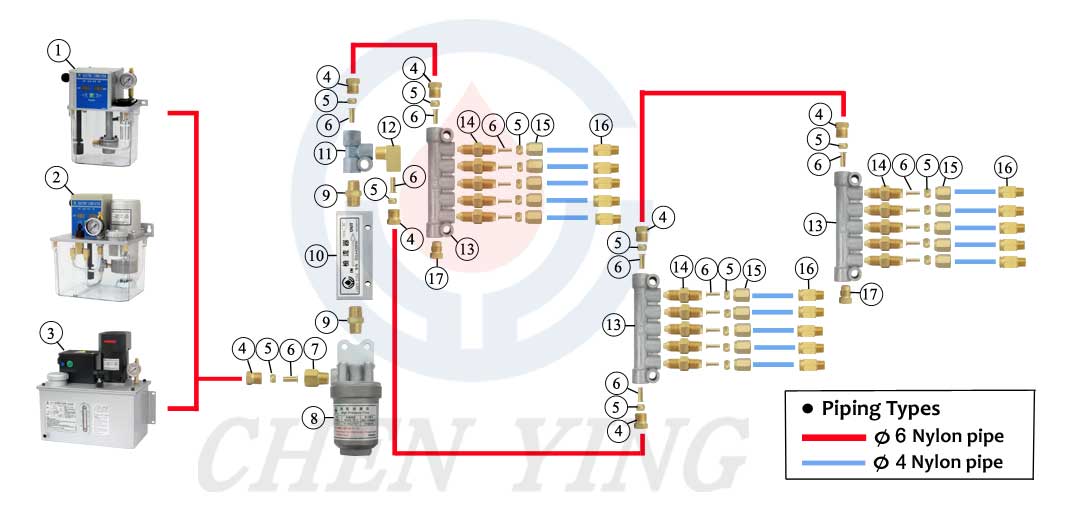

Most lubricant requirements are determined based on experience and actual measurements. While calculation formulas can provide estimates for the amount of lubricant needed for different components, these calculations may not always be accurate. Several factors can influence the lubricant requirements, including the materials of the friction surfaces, their surface roughness, and the operating conditions such as speed, rotational speed, load, and ambient temperature. Additionally, harmful substances in the environment, the type of lubricant used, and sealing conditions can also play a role. Therefore, it is important to adjust the lubricant amount according to these various factors. Typically, the appropriate lubricator model can be selected based on the total lubricant consumption at the lubrication point, and from there, suitable piping components can be chosen for the lubricator. A schematic diagram of an oil resistance type lubrication system is provided below.

| NO | Lubricator Model | NO | Parts | NO | Parts | NO | Parts | NO | Parts |

| 1 | CEN-02 | 4 | Compression Bushing | 8 | Oil Filter | 12 | Elbow Adapter | 16 | Quick Straight Adapter |

| 2 | CENA-25W | 5 | Compression Sleeve | 9 | Connector | 13 | A-7 Type Distributor | 17 | Closure Plug |

| 3 | CEV-60W | 6 | Tube Insert | 10 | Magnetic Sensor Reed Switch | 14 | RC Oil Meter Adapter | ||

| 7 | Straight Adapter | 11 | 3-Way Junction | 15 | Compression Nut |

How to select the right size of oil tank for your lubricator?

Chen Ying offers a variety of tank capacity options to meet different needs. In addition to considering the suitable material for the lubricant, the selection should also take into account the total lubricant consumption of the lubrication points and the frequency of lubricant replenishment. For example, if we choose a 3L tank, it's recommended to add lubricant every three months. This is mainly to prevent the lubricant from deteriorating past its shelf life, which could damage mechanical parts or metal components.

|

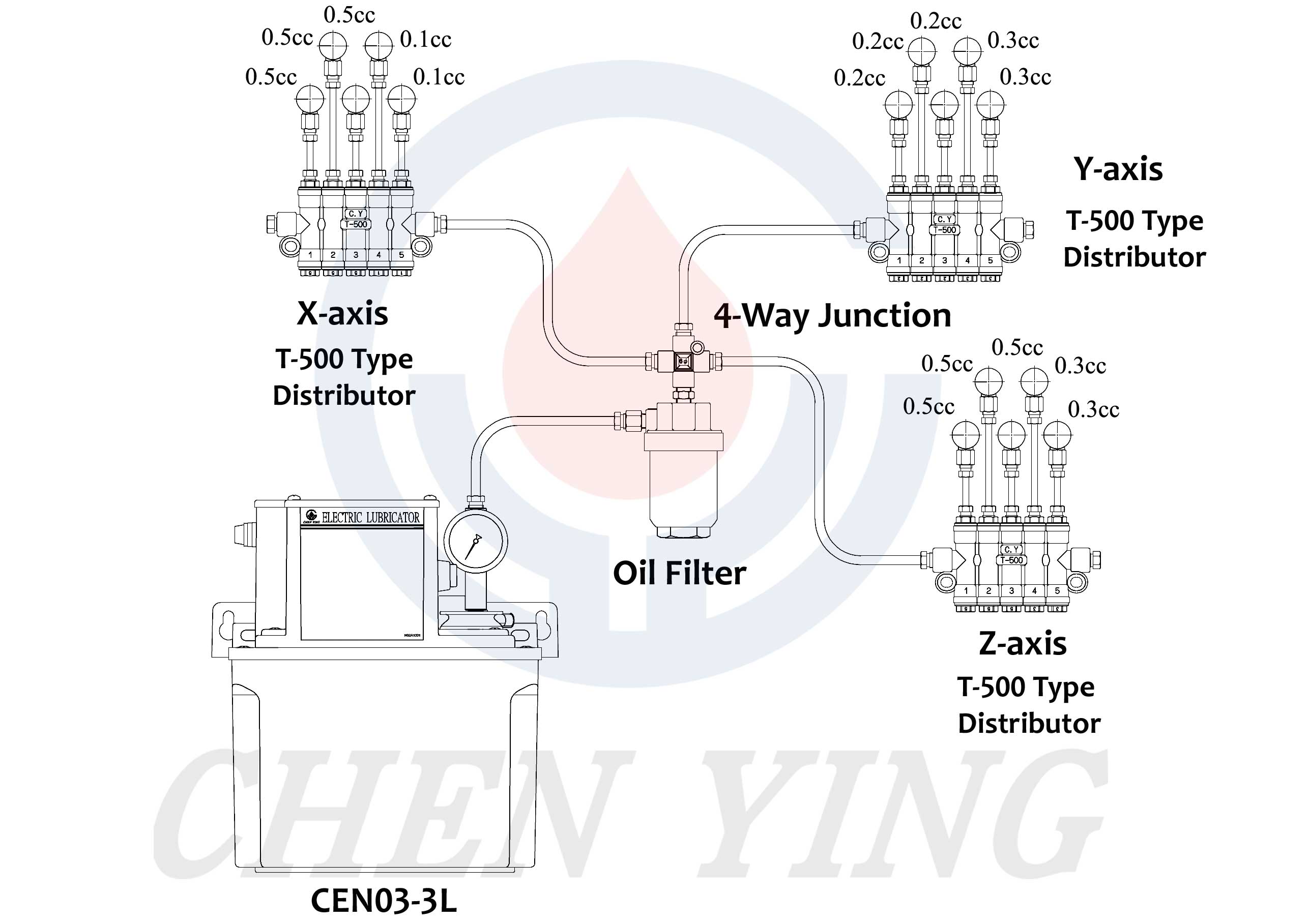

X-axis |

Lubrication Point | 1 | 2 | 3 | 4 | 5 | Total flow rate |

| Flow Rate | 0.5 cc | 0.5 cc | 0.5 cc | 0.1 cc | 0.1 cc | 1.7 cc | |

|

Y-axis |

Lubrication Point | 1 | 2 | 3 | 4 | 5 | Total flow rate |

| Flow Rate | 0.2 cc | 0.2 cc | 0.2 cc | 0.3 cc | 0.3 cc | 1.2 cc | |

|

Z-axis |

Lubrication Point | 1 | 2 | 3 | 4 | 5 | Total flow rate |

| Flow Rate | 0.5 cc | 0.5 cc | 0.5 cc | 0.3 cc | 0.3 cc | 2.1 cc | |

|

Formula for calculation: X-axis (Total flow rate) +Y-axis (Total flow rate) + Z-axis (Total flow rate) = Total oil consumption

1.7+1.2+2.1=5cc |

|||||||

Assuming a total oil consumption of 5cc per hour, and a 4-hour cycle per day, the daily cycle count would be 24 hours/day ÷ 4 hours/cycle = 6 cycles. Therefore, the total daily oil consumption is 6 cycles * 5cc/cycle = 30cc. For three months, the total oil consumption would be 30cc/day * 90 days = 2.7 liters. Hence, it is recommended to choose a 3L oil tank.