11.Automatic Grease Lubrication System: Equipment, Applications, and Solutions

Automatic Grease Lubrication System: Equipment, Applications, and Solutions

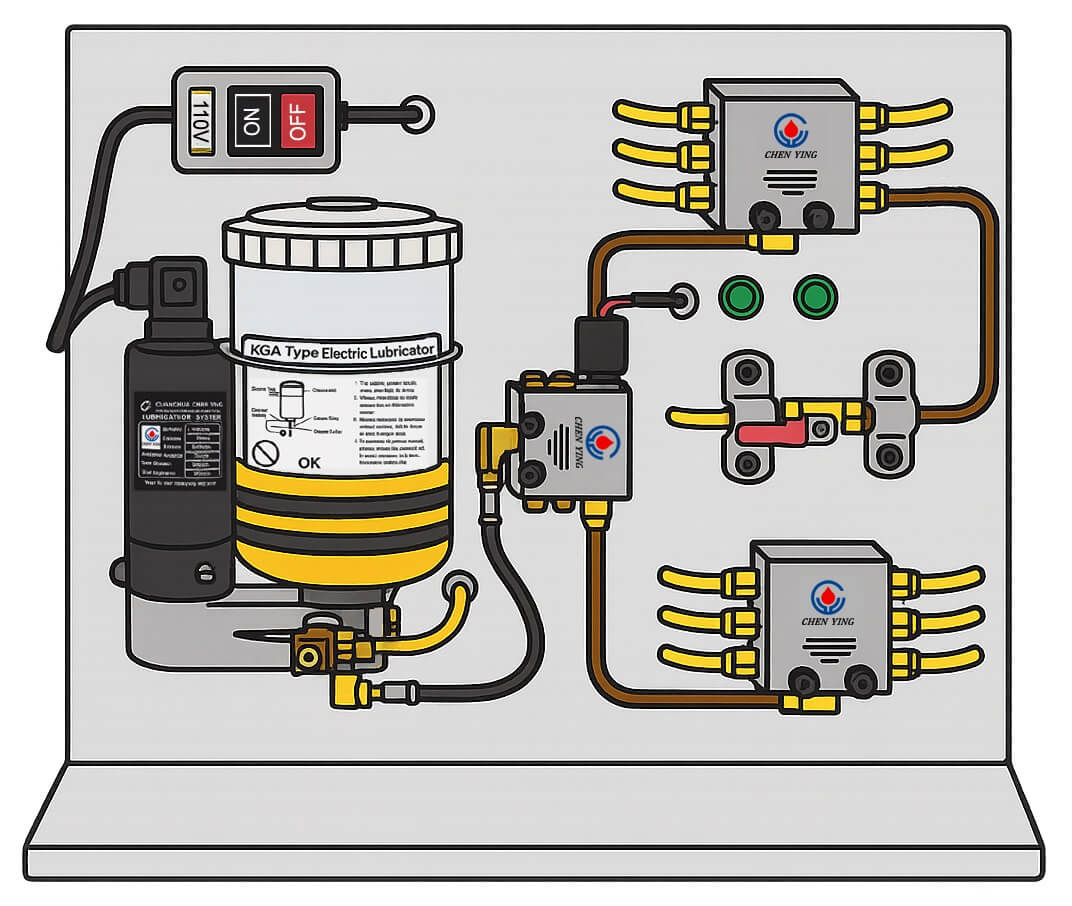

An Automatic Grease Lubrication System (AGLS) is a centralized grease lubrication system designed to automatically deliver accurately measured grease to multiple lubrication points of industrial and heavy-duty equipment. By replacing manual greasing operations, the system ensures stable lubrication, reduces friction and wear, prevents contamination, and significantly improves equipment reliability, uptime and operating life.

Modern industrial applications demand stable lubrication under continuous operation, high load, vibration, and harsh environmental conditions. An Automatic Grease Lubrication System ensures the right amount of grease is delivered at the right time—fully eliminating the common problems of over-lubrication and under-lubrication.

System Overview

By using pump pressure, grease is evenly distributed to all lubrication points, enabling continuous and stable lubrication—even while equipment remains in operation.

An AGLS supplies grease according to preset intervals and volumes while the machine remains in operation. A complete Automatic Grease Lubrication System typically includes:

-

Grease

Pump:

Provides pressure to deliver grease across the system. Options include electric, pneumatic, and manual-assisted configurations.

-

Grease

Reservoir:

Grease

reservoirs are available in cup-type and bellows-type designs, providing

flexible solutions for different system requirements. A cup-type grease

reservoir supports both manual and pneumatic refilling, offering flexible

capacity options. However, proper handling during refilling is essential to

prevent air ingress and contamination, which may affect lubrication

performance.

A

bellows-type grease reservoir, also known as a bellows-type

grease cartridge, is a sealed and collapsible grease container designed

to dispense grease without air intake. This design effectively reduces

contamination risks and maintenance downtime, while ensuring stable and

reliable grease delivery for automatic lubrication systems.

-

Piping

Network:

High-pressure tubing designed to withstand grease viscosity, delivery

pressure, and mechanical vibration.

-

Distributor/Metering

Valves:

Precisely regulate the grease to each lubrication point. Depending on system design,

metering devices may include progressive divider blocks, dual-line metering

valves, single-line injectors, or micro-dosing elements.

Related Products: CFB Type Grease Volumetric Distributor or CV Type Progressive Feeder

Provides pressure to deliver grease across the system. Options include electric, pneumatic, and manual-assisted configurations.

High-pressure tubing designed to withstand grease viscosity, delivery pressure, and mechanical vibration.

Precisely regulate the grease to each lubrication point. Depending on system design, metering devices may include progressive divider blocks, dual-line metering valves, single-line injectors, or micro-dosing elements.

Related Products: CFB Type Grease Volumetric Distributor or CV Type Progressive Feeder

-

Control

Unit (e.g., PLC or timer):

Manages lubrication intervals, pressure

monitoring, cycle timing, fault detection, and alarm outputs. Ensures proper

system functionality and predictive maintenance capability. With automatic

delivery at preset intervals and accurate metering volumes, the system

stabilizes lubrication performance and reduces maintenance costs throughout the

machine’s lifecycle.

Manages lubrication intervals, pressure monitoring, cycle timing, fault detection, and alarm outputs. Ensures proper system functionality and predictive maintenance capability. With automatic delivery at preset intervals and accurate metering volumes, the system stabilizes lubrication performance and reduces maintenance costs throughout the machine’s lifecycle.

Automatic Grease Lubrication System eliminates the common problems of over-lubrication and under-lubrication that naturally occur with manual maintenance.

Comparison: Automatic vs. Manual Lubrication

|

Item |

Manual Lubrication |

Automatic Lubrication System |

|

Lubrication Consistency |

Operator-dependent, excessive or insufficient lubrication |

Precise and consistent dosing with stable performance |

|

Labor Costs |

High labor request |

reduced manpower and maintenance time |

|

Machine Downtime |

Requires shutdown for lubrication |

lubrication during operation |

|

Safety |

Direct exposure to heat or hazardous areas |

No manual contact needed, higher safety |

|

Component Lifespan |

Shortened due to inconsistent lubrication |

30–50% service life extension |

System Types and Configurations

To support different machine structures and lubrication requirements, Automatic Grease Lubrication System(AGLS) can be configured in several types:

Lubrication System Type

Key Features

Resistance Lubrication Type

Simple

structure and economical installation. Suitable for small

to medium machines with moderate lubrication demands. Relies on pressure and line resistance for grease flow.

Progressive Lubrication Type

Uses

progressive dividers to sequentially deliver grease. Ideal for equipment with

many lubrication points and offers clog-detection capability.

Back-Pressure / Pressurized Lubrication Type

Uses

pressure-controlled metering devices to ensure stable output even under long

piping distances, high back-pressure, or demanding

environmental conditions.

Dual-Line Lubrication Type

Designed for

large-scale equipment with long lubrication distances. Alternates between two

main lines for reliable grease delivery in harsh environments such as steel mills or mining operations.

Micro Grease Lubrication Type

Provides

ultra-small, precisely metered grease quantities for high-speed or

high-precision mechanisms requiring minimal residual grease.

Industrial Lubrication Applications

Automatic grease lubrication systems are widely used across industries including:Heavy machinery and construction equipment

CNC machines and industrial automation machinery

Mining, quarrying, and material processing

Steel, metalworking machinery, and foundry applications

These systems ensure consistent lubrication even under harsh environments such as dust, high temperature, and heavy load, intermittent operation, and outdoor conditions.Transportation fleets and commercial vehicles and agricultural equipment

Advantages of an Automatic Grease Lubrication System

Accurate and consistent grease delivery Reduced downtime and energy consumption Lower maintenance labor cost and improved workplace safety

Extended bearing and mechanical component life Enhanced system reliability and stability under continuous operation Enhanced equipment reliability and productivity

Conclusion

An Automatic Grease Lubrication System is essential for modern industry, providing precise, reliable, and highly efficient lubrication performance. With years of expertise in Centralized Lubrication System design and manufacturing, Chen Ying offers comprehensive lubrication solutions tailored to diverse industrial needs. Selecting the right system type and maintaining proper operation ensures long-term equipment protection and stable production performance.

Related Links:

How to Choose the Right Lubrication System for Your CNC Machine?

How to Choose the Right Automatic Lubrication System