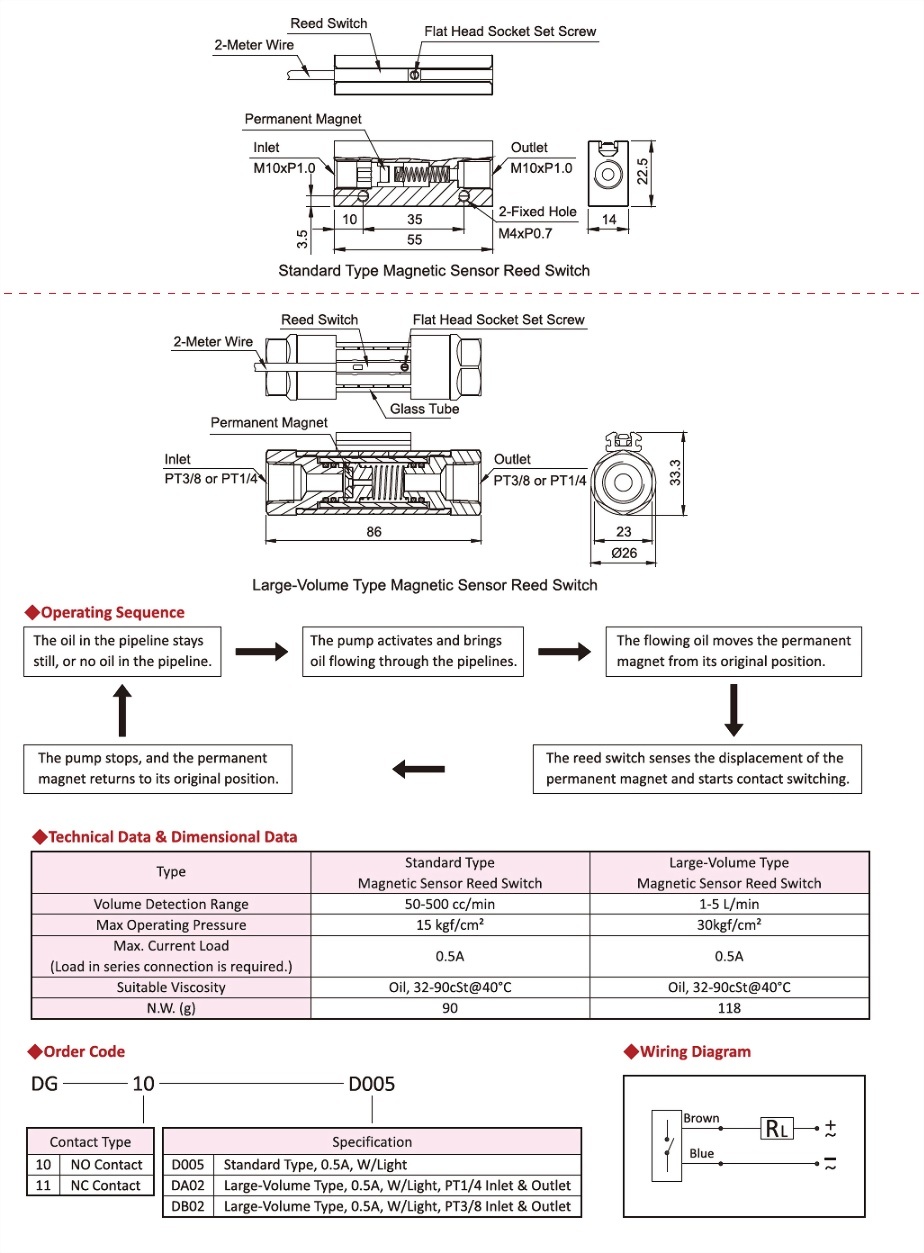

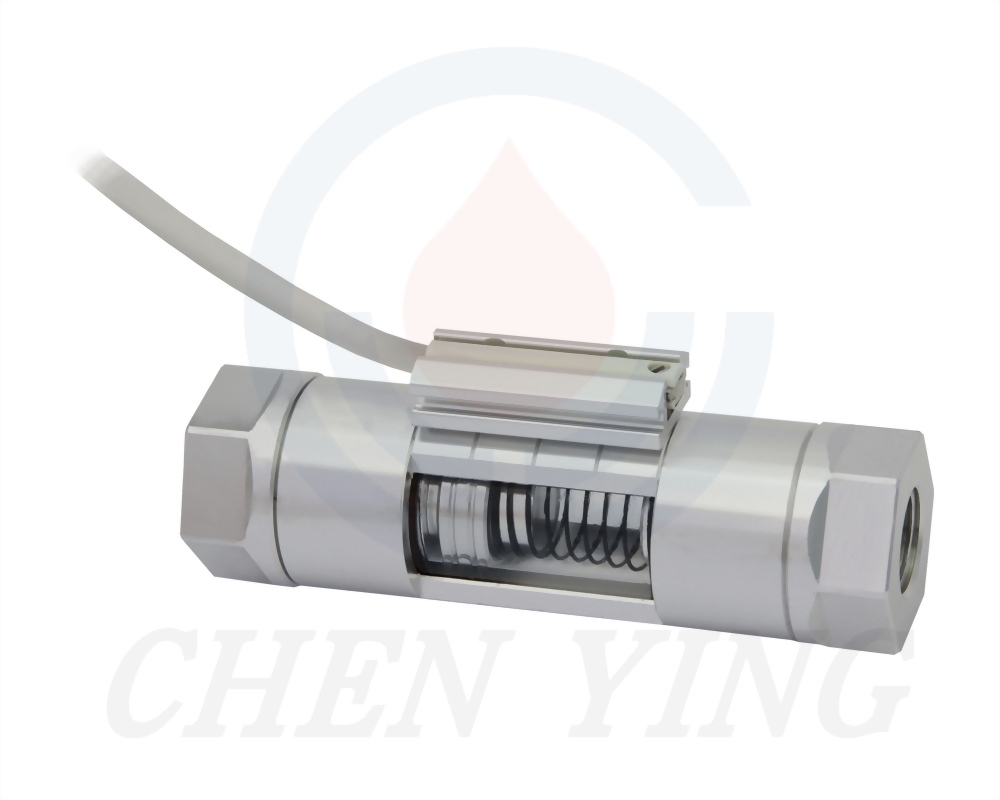

Magnetic Sensor Reed Switch (Standard Type / Large-Volume Type)

-

There are two contact types for magnetic sensor reed switches:

● NO Contact: It sends a continuous signal when the oil flows through the pipes.

● NC Contact: It sends a continuous signal when the oil does not flow through the pipes. - The movement of the permanent magnet activates the reed switch contacts without touching the oil in the pipe.

- The user can place the reed switch in the required position. Its anti-vibration capability prevents sending false signals during vibration.

- The installation angle of the magnetic sensor reed switch is not restricted, and the detection function is not affected by either vertical or horizontal positions.

- A large-volume type magnetic sensor reed switch can work with a BS type transparent adjustable distributor's volume control base, extending to a maximum of six outlets optionally. It can adjust and monitor multi-pipe flow simultaneously.

- Recommend working with oil filters with magnets inside that can filter iron filings from interfering with the permanent magnet of the sensor reed switch.

- The standard type is suitable to work with resistance type or circulating type oil lubricators.

- The large-volume type is suitable for the motor with a rotary oil pump (CYP-10A to CYP-13A) and circulating oil type lubricators.

- The volume of oil would be less after flowing through the magnetic sensor reed switch due to it creates resistance when the oil enters.

- The max flow rate and max pressure that the magnetic sensor reed switch can handle are affected by various factors, such as lubricant, temperature, viscosity, and spring force.