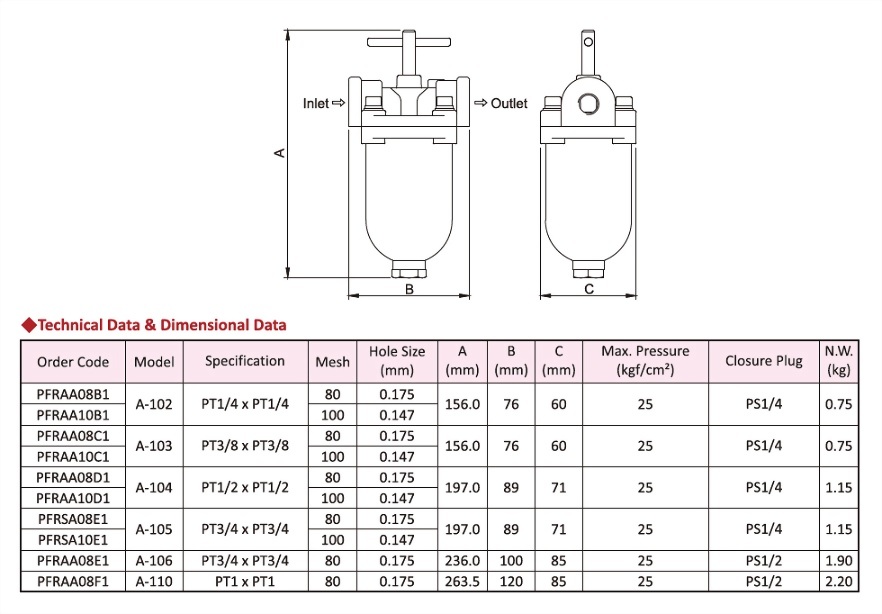

Oil Auto Cleaner

- Oil auto cleaners are widely used in pipeline filtration of lubrication and hydraulic systems and other industries to maintain the performance of mechanical equipment.

- The body of the oil auto cleaner is made of highly durable zinc alloy with a combination of large, small, and side stainless steel (SUS304) gaskets to form a filtration structure.

- Oil auto cleaners can be cleaned at any time during the operation without shutting down the machine. It can save time for maintenance.

- The suitable viscosity range is 10~220cSt@40°C. The operating temperature is 0~90°c.

- Recommend working with Chen Ying's lubrication systems, which consist of rotary and heavy oil pumps with motors.

- To clean the oil auto cleaner during the machine operation time, release the bottom closure plug of the oil auto cleaner first. Then, turn the cross handle left and right several times to remove the impurities of the gaskets. When the impurities flow out with oil, tighten the closure plug to complete the cleaning process.

- The bottom closure plug can be replaced with a ball valve for easy maintenance regularly, but the pressure resistance value will be reduced accordingly.

- The volume of lubricant would be less after flowing through the oil auto cleaner due to the filtration structure creating resistance when the lubricant enters.

- The max flow rate of an oil auto cleaner is affected by various factors, such as lubricant, temperature, viscosity, flow rate, pressure, size of the passing area, mesh numbers, and bore size of inlets and outlets.