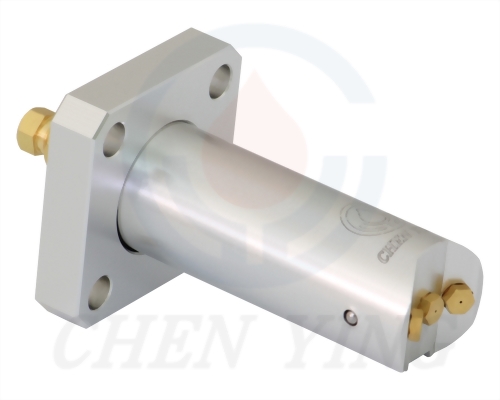

POM Minimum Quantity Oil Pneumatic Lubricator

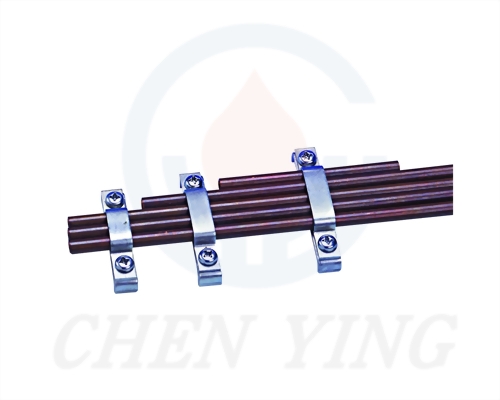

- Metered Qil Quantity

- Pneumatic Lubrication

-

Adjustable Oil Quantity

-

Minimum Quantity Grease Lubricators Available for Selection.

- The discharge volume of POM is precise and can be adjusted from 0.01cc to 0.08cc per stroke.

-

POM can be actuated either by a frequency generator or a solenoid valve.

● The pneumatic pressure supply drives the frequency generator, and the user can adjust each stroke frequency upon demand. The service life is ten million cycles.

● The input voltage powers the solenoid valve, and the PLC can precisely control its stroke frequency. The solenoid valve works as the ON/OFF switch of the pneumatic pressure supply. The service life is two million cycles. - POM requires 4-8kgf/cm2 pneumatic pressure supply to operate.

- The standard POM has one outlet, which can be increased to four on request. Do not plug any outlet of POM.

- POM has an oil volume adjuster for adjusting the discharge volume. The fixed oil volume screw hole secures the oil volume adjuster to prevent its setting from being changed.

- The air-regulating valve can adjust the air volume upon the need. Turn the air-regulating valve clockwise to decrease the air volume and turn it anti-clockwise to increase the air volume.

- All POM lubricators have 80-mesh oil filters. The oil inlet of the 2L-square tank has an additional 40-mesh oil filter to filter the impurities.

- Each outlet of POM can add a reed switch to detect if stroke movements are regular.

- 2L square tank and 2000cc cylindrical tank can add a float switch to detect oil level automatically.

- Recommend using vegetable oil viscosity 22~68cSt@40 °C. Forbid filling cutting fluid and volatile lubricants, such as alcohols and ethylene glycol-based lubricants.

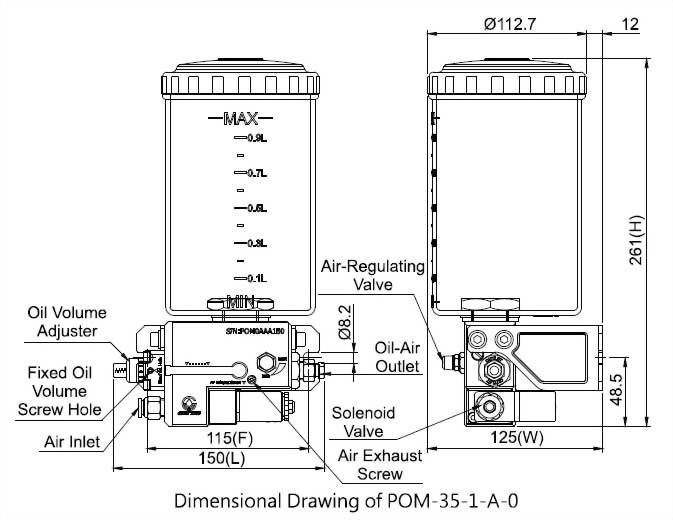

◆ Dimensional Data

Model

Tank Capacity

Fixed Hole Distance (mm)

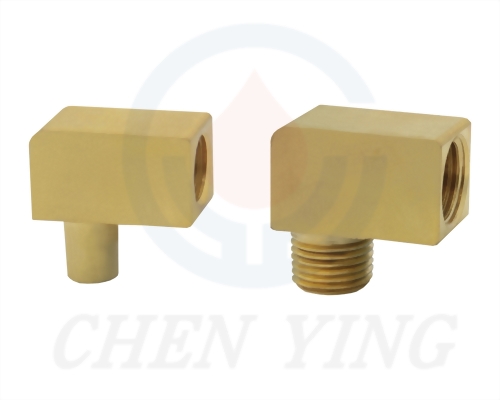

Oil-Air Outlet Number

Length (mm)

Width (mm)

Height (mm)

N.W. (kg)

Without Float Switch

With Float

Switch

Without Float

Switch

With Float

Switch

POM-01

2L Square Oil Tank

115

1

169

121

247

273

2.3

2.4

2

275

301

2.7

2.8

3

304

330

3.1

3.2

4

332

358

3.4

3.6

POM-35

1L Cylindrical Oil Tank

115

1

150

125

261

--

1.5

--

2

290

--

2.0

--

3

318

--

2.4

--

4

347

--

2.8

--

POM-50

2L Cylindrical Oil Tank

115

1

154

135

346

394

1.7

1.9

2

374

423

2.1

2.3

3

403

451

2.5

2.7

4

431

480

2.9

3.1

◆ Technical Data

Method

of Actuation

Solenoid

Valve

Frequency

Generator

Voltage

AC110V

AC220V

DC24V

--

Ampere

0.1A

0.1A

0.2A

--

Pneumatic

Pressure

4-8kgf/cm²

Discharge

Volume

0.01cc-0.08cc/stroke

(Adjustable)

Air

Inlet

Ø8

Oil-Air

Outlet

Float

Switch

Optional (NC or NO

Contact).Only available for 2L tank

Reed

Switch

Optional (NC or NO Contact)

Suitable

Viscosity

Vegetable

Oil, 22-68cSt@40oC

◆ Pressure Chart (Reference Value)

Pneumatic

Pressure(kgf/c㎡)

4

5

6

7

8

Air Consumption(L/min)

102

127

145

156

160

◆ Order Code

Model

Tank Capacity

Oil-Air Outlet Number

Method of Actuation

Oil-Air Outlet Bore

Special Request

POM

35

1

1

0

※

01

2L Square Tank

1

1 Outlet

1

Frequency Generator

0

Ø4

TC

Add a NC Contact Reed

Switch

35

1L Cylindrical Tank

2

2 Outlets

A

Solenoid Valve,

AC110V

1

Ø6

TO

Add a NO Contact Reed

Switch

50

2L Cylindrical Tank

3

3 Outlets

C

Solenoid Valve,

AC220V

2

Ø8

SC

Add a NC Contact

Float Switch(Only available for 2L tank)

4

4 Outlets

K

Solenoid Valve, DC24V

SO

Add a NO Contact

Float Switch(Only available for 2L tank)