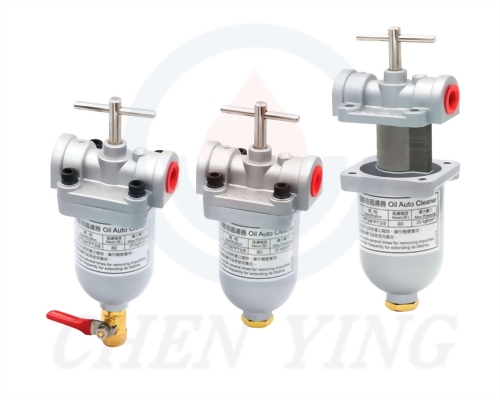

CLST Circulating Type Oil Electric Lubricator with Cooler

- Proportional Oil Quantity

-

Automatic Lubrication Controlled by PLC

- CLST has a highly efficient air cooler that reduces the oil temperature to room temperature plus 10°C.

- CLST has a cyclic inlet that allows the oil to return to the oil tank, which saves the consumption of oil.

- CLST has a magnetic filter inside the cyclic inlet that prevents iron filings from entering the oil tank to maintain the cleanness of the circulating oil.

- The operation and interval time of CLST are controlled by PLC. CLST also can operate continuously without interval time.

- The rotary oil pump of CLST is made of special aluminum alloy and assembled with the 1/4HP motor to provide stable output pressure, low operating noise, and long service life.

- CLST has a pressure-regulating valve that enables the user to adjust the operating pressure.

- CLST has a NC contact float switch that detects the oil level automatically and sends signals when the oil level is low.

-

After installing CLST and connecting all oil pipes, let CLST continue running until oil fulfills all oil pipes. The lubricator is ready to use when the oil flows out to remove the air bubbles.

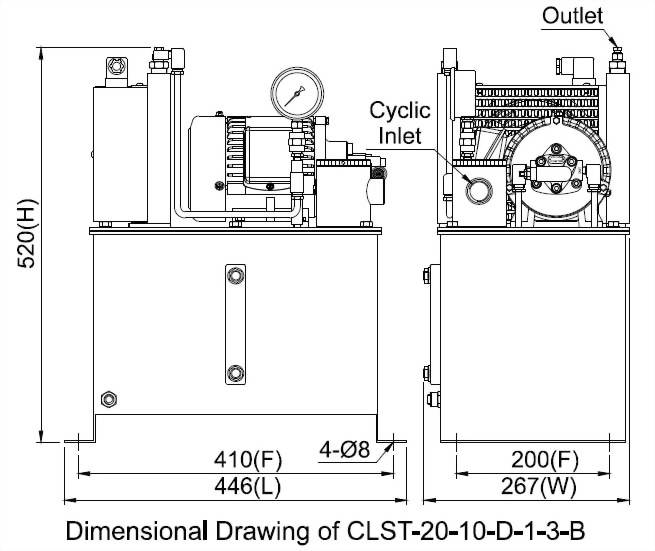

◆ Dimensional Data

Tank

Capacity

Tank Material

Length (mm)

Width (mm)

Height (mm)

Fixed Hole

Distance (mm)

N.W. (kg)

20L

Iron

446

267

520

410x200

29.5

36L

Iron

410

353

655

300x215

41.5

64L

Iron

560

480

655

450x300

54.4

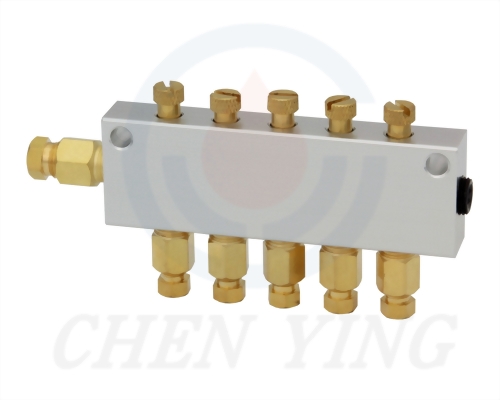

◆ Technical Data

Motor

Power (Number of Poles)

1/4HP

(4P)

Voltage

1Ø110V,

1Ø220V, Three Phase

Rotary Oil Pump

CYP-10A

CYP-11A

CYP-12A

CYP-13A

Max. Discharge Volume

1.1-1.4

L/min

2.2-2.7

L/min

3.7-4.5

L/min

6.5-7.9

L/min

Max. Operating Pressure

5kgf/c㎡

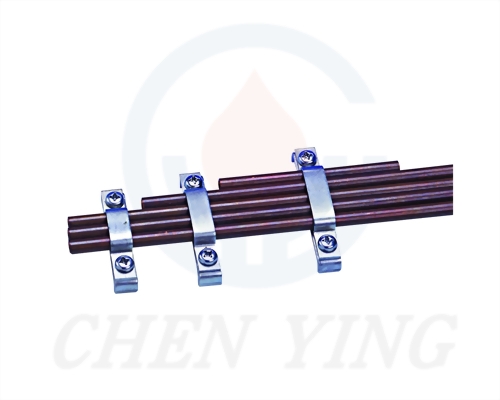

Discharge Bore

Ø4, Ø6

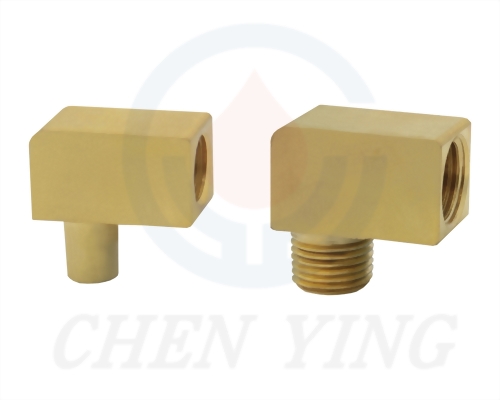

Cyclic Inlet

PT1/2, PT3/4

Float Switch

NC Contact (NO Contact on request)

Suitable Viscosity

Oil, 32-68 cSt@40℃

◆ Order Code

Model

Tank

Capacity(Material)

Rotary

Oil Pump

Voltage

Motor Power

Discharge Bore (PT3/8)

Cyclic Inlet

Special Request

CLST

20

10

D

1

3

B

※

20

20L

(Iron)

10

CYP-10A

A

1Ø110V

1

1/4HP

2

Ø4

W/Pressure Gauge

A

PT1/2

SO

NO

Contact Float Switch

30

30L

(Iron)

11

CYP-11A

C

1Ø220V

3

Ø6

W/Pressure Gauge

B

PT3/4

36

36L

(Iron)

12

CYP-12A

D

3Ø220/380V

40

40L

(Iron)

13

CYP-13A

E

3Ø220/440V

60

60L

(Iron)

F

3Ø208/415V

64

64L

(Iron)

G

3Ø230/460V

77

77L

(Iron)

H

3Ø240/480V

100

100L

(Iron)

M

3Ø220V

130

130L

(Iron)

N

3Ø380V

150

150L

(Iron)

X

Special Voltage

204

204L

(Iron)

※A standard dual-voltage motor is connected for low voltage. Please specify if you need it to be connected for high voltage when placing an order.

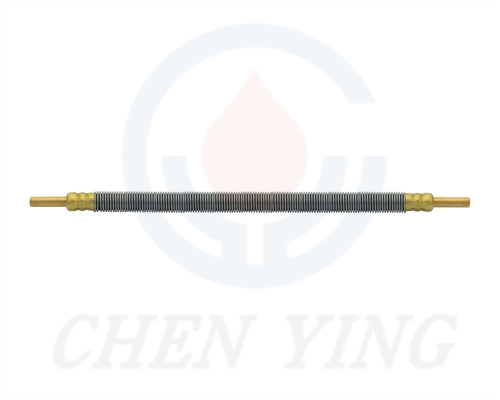

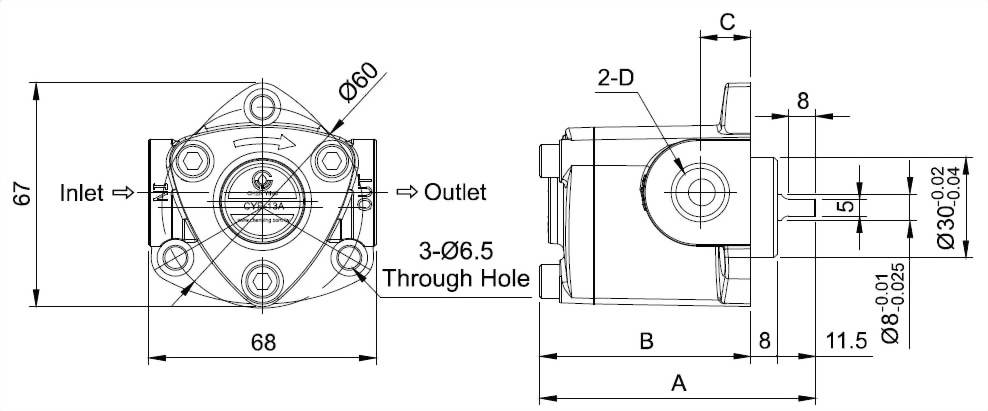

◆The dimensional and technical data of rotary oil pump is as described below.

◆Dimensional Data & Technical Date

| Model | Applicable Rotational Speed(min-1) | Discharge Voluma(L/min) | A(mm) | B(mm) | C(mm) | D Bore | Max. Pressure | Suitable Viscosity | Suitable Temp. Range | N.W.(g) |

| CYP-10A | 1420-1720 | 1.1-1.4 | 60.5 | 41 | 12 | PT1/8 | 5 kgf/cm2 | 32-68 cSt@40℃ | 0-90℃ | 616 |

| CYP-11A-1 | 1420-1720 | 2.2-2.7 | 64.5 | 45 | 12 | PT1/8 | 665 | |||

| CYP-11A-2 | 1420-1720 | 2.2-2.7 | 64.5 | 45 | 12 | PT1/4 | 664 | |||

| CYP-12A | 1420-1720 | 3.7-4.5 | 70.5 | 51 | 12 | PT1/4 | 751 | |||

| CYP-12L | 450-1200 | 1.1-3.0 | 62.5 | 43 | 11 | PT1/4 | 650 | |||

| CYP-13A | 1420-1720 | 6.5-7.9 | 82.5 | 63 | 15 | PT3/8 | 924 |

※ IF you need to add an adjustable pressure valve to the rotary oil pump,please add AV after the model number when you place an order. For example,CYP-11A-1-AV stands for one set of CYP-11A-1 assembled with CYP-AV.

※After adding the adjustable pressure valve,the net weight increases by 110g.