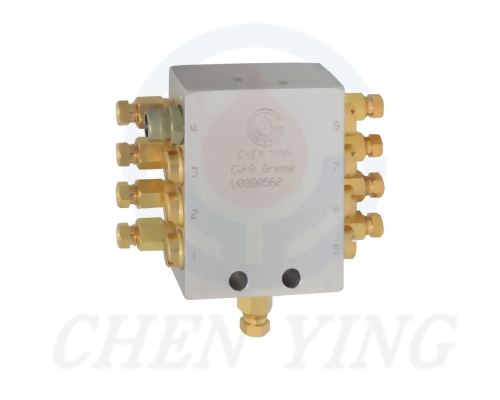

MAG Resistance Type Grease Pneumatic Lubricator

- Proportional Grease Quantity

-

Pneumatic Lubrication

- The operation and interval time of MAG are controlled pneumatically.

- A solenoid valve can be added as a switch for the pneumatic pressure supply to control the ON/OFF switch of MAG upon request.

- The operation time (ON) should be set up as 25 seconds, and the interval time (OFF) should be set up as 5 seconds to complete one operation cycle.

- MAG requires 4-8kgf/cm2 pneumatic pressure supply to have the corresponding 117-290kgf/cm2 operating pressure. It can meet different pressure requirements and applications.

- Please refill grease from the grease inlet to prevent air and impurities from entering the grease tank.

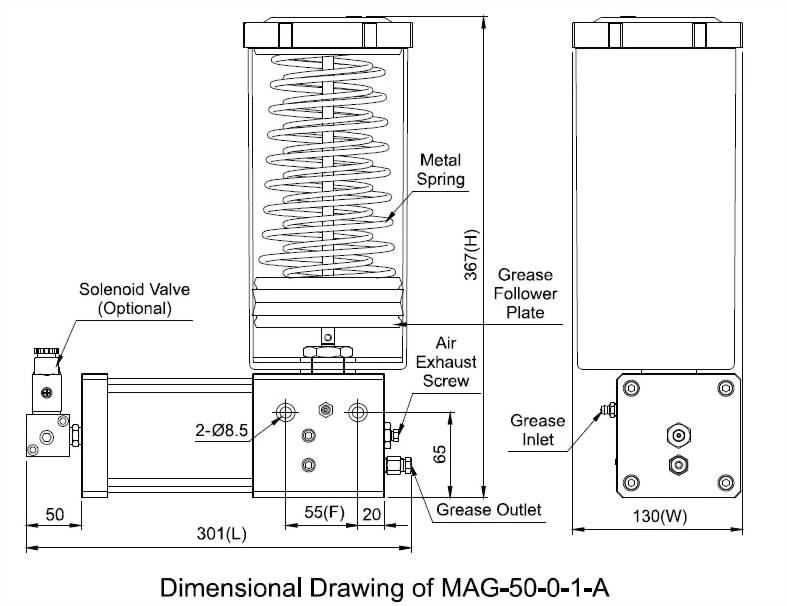

◆ Technical Data & Dimensional Data

Effective

Capacity

Length (mm)

Width (mm)

Height (mm)

Fixed Hole

Distance (mm)

Operation Time

Interval Time

Discharge

Volume

Grease Inlet

Air Inlet

Discharge Bore

Suitable

Viscosity

N.W.(kg)

1500cc

301

130

367

55

Over 25 sec.

Over 5 sec.

About

2.5cc/stroke

PT1/8

Grease Nipple

Ø8、Ø10

Ø4、Ø6、Ø8、Ø10

Grease

NLGI 000-2

6.53

◆ Pressure Chart (Reference Value)

Pneumatic

Pressure (kgf/c㎡)

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

Operating

Pressure (kgf/c㎡)

117

140

160

181

201

222

242

265

290

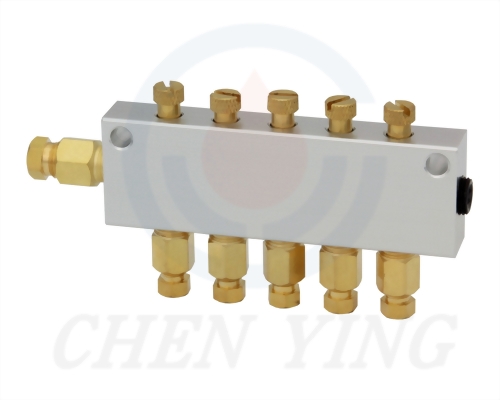

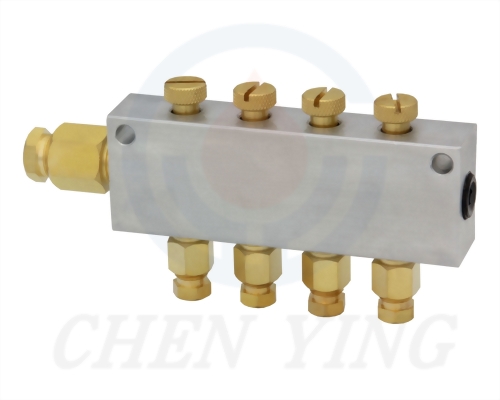

◆ Order Code

Model

Effectiv Capacity

Air

Inlet

Discharge Bore

Solenoid Valve

Special Request

MAG

50

0

1

0

※

50

1500cc

0

Ø8

0

Ø4 x PT1/4

0

Without a Solenoid Valve

G

Add a Pressure Gauge

1

Ø10

1

Ø6 x PT1/4

A

With a Solenoid Valve, AC110V

RC

Add a NC Contact

Magnetic Level Switch

2

Ø8 x PT1/4

C

With a Solenoid Valve, AC220V

RO

Add a NO Contact

Magnetic Level Switch

3

Ø10 x PT1/4

K

With a Solenoid Valve, DC24V