POM-AP Minimum Quantity Grease Pneumatic Lubricator

- Metered Grease Quantity

- Pneumatic Lubrication

-

Adjustable Grease Quantity

-

Grease Cartridge

-

Minimum Quantity Oil Lubricators Available for Selection

- The discharge volume of POM-A and POM-AP is precise and can be adjusted from 0.01cc to 0.08cc per stroke.

-

POM-A and POM-AP can be actuated either by a frequency generator or a solenoid valve.

● Pneumatic pressure supply drives the frequency generator, and the user can adjust each stroke frequency upon the demand. The service life is ten million cycles.

● The input voltage powers the solenoid valve, and the PLC can precisely control its stroke frequency. The solenoid valve works as the ON/OFF switch of the pneumatic pressure supply. The service life is two million cycles. - POM-A and POM-AP require 4-8kgf/cm2 pneumatic pressure supply to operate.

-

The standard POM-A and POM-AP have one outlet, which can be increased to two on request. Do not plug any outlet of POM-A and POM-AP.

- POM-A and POM-AP have grease volume adjusters for adjusting the discharge volume per stroke. It is fixed by the grease volume screw to prevent its setting from being changed easily.

- Each outlet of POM-A can add a reed switch for monitoring every stroke.

- A magnetic level switch can be added to POM-A and POM-AP on request to detect the grease level automatically.

- An OT spray gun with the φ4 inlet bore can work with either POM-A or POM-AP to have the grease mist effect.

- Please refill grease from the grease inlet to prevent air and impurities from entering the grease tank.

-

POM-AP-07 works with a 700cc disposable grease cartridge. When the grease is empty, replace POM-AP-07 with a new grease cartridge. Standard POM-AP-07 does not include a grease cartridge but is available upon request.

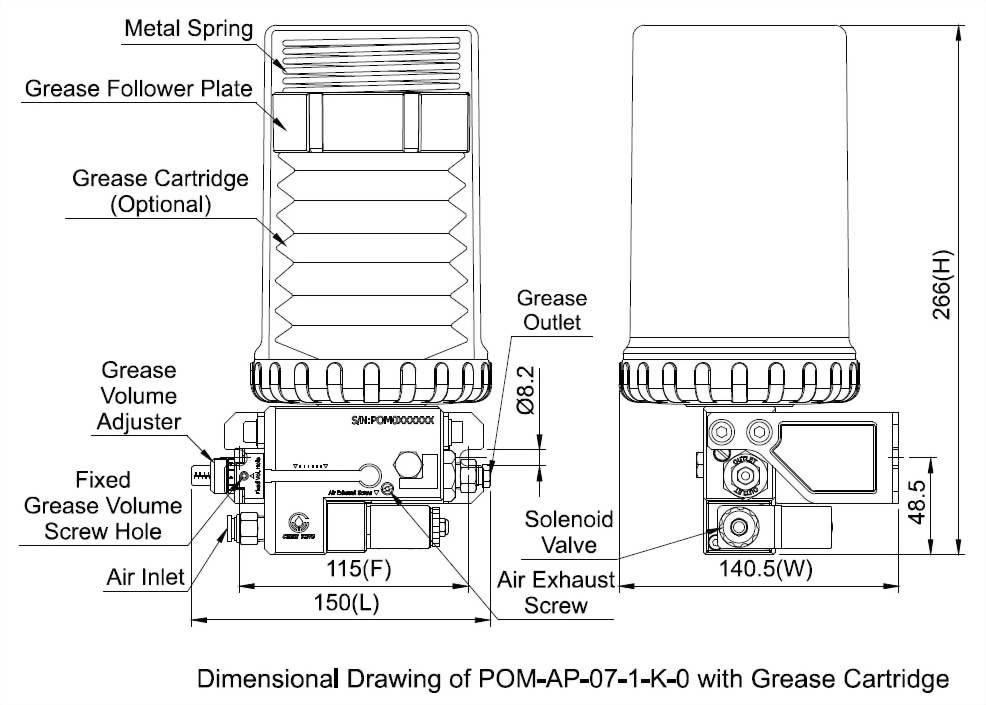

◆ Dimensional Data

Model

Effective

Capacity

Fixed Hole

Distance (mm)

Length (mm)

Width (mm)

Height (mm)

Outlet Number

N.W. (kg)

POM-AP-07

700cc

Grease Cartridge

115

150

140.5

266.0

1

1.82

294.5

2

2.23

POM-AP-40

550cc

115

150

125.0

304.5

1

1.94

330.0

2

2.35

POM-AP-50

1500cc

115

154

135.0

345.5

1

3.02

374.0

2

3.43

◆ Technical Data

Method

of Actuation

Solenoid

Valve

Frequency

Generator

Voltage

AC110V

AC220V

DC24V

--

Ampere

0.1A

0.1A

0.2A

--

Pneumatic Pressure

4-8kgf/cm²

Discharge Volume

0.01cc-0.08cc/stroke

(Adjustable)

Air Inlet Bore

Ø8

Discharge Bore

Ø4

Magnetic Level Switch

Optional

(NC or NO Contact)

Reed Switch

Optional (NC or NO Contact)

Suitable Viscosity

POM-AP-07:Grease,

NLGI 000-0

POM-AP-40, POM-AP-50:Grease, NLGI 1, 2

◆ Order Code

Model

Tank Capacity

Outlet

Number

Method of Actuation

Discharge Bore

Special Request

POM-AP

07

1

K

0

※

40

550cc

1

1 Outlet

1

Frequency Generator

0

Ø4

RC

Add a NC Contact

Magnetic Level Switch

50

1500cc

2

2 Outlets

A

Solenoid Valve,

AC110V

RO

Add a NO Contact

Magnetic Level Switch

07

700cc Grease

Cartridge

C

Solenoid Valve,

AC220V

TC

Add a NC Contact Reed

Switch

K

Solenoid Valve, DC24V

TO

Add a NO Contact Reed

Switch

※Please refer to the 700cc Grease Cartridge catalog if you need to purchase one.

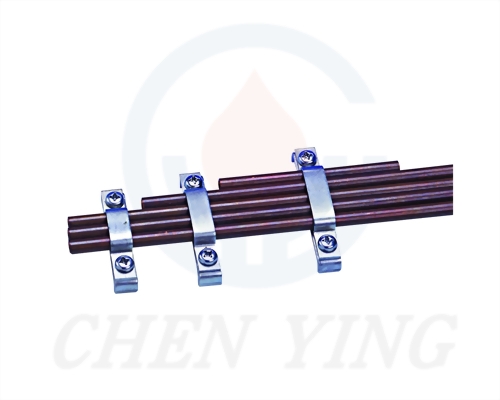

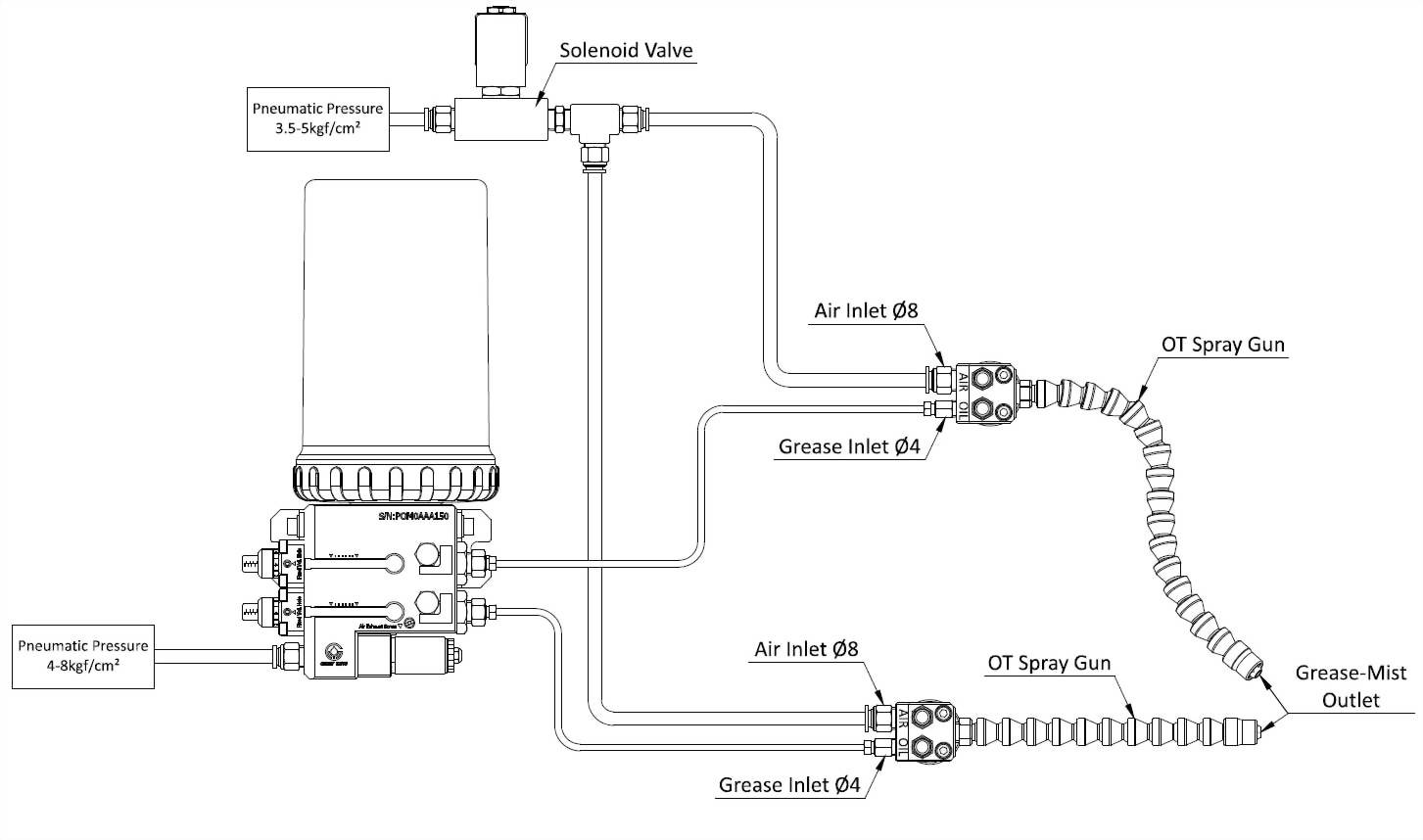

◆ Minimum Quantity Grease Lubrication System Installation Schematic Diagram

◆ The dimensional and technical data of 700cc Grease Cartridge is as described below

◆ Order Code

| Order Code | Grease Type | Grease Viscosity | Minimum Order Quantity Requirement |

| I01D0021 | Mobilux EP023 | NLGI 000 | -- |

| I01D0012 | Mobil EP0 | NLGI 0 | -- |

| I01D0013 | Mobil EP1 | NLGI 1 | 100 |

| I01D0029 | Idemitsu Polylex UMF | NLGI 000 | 6 |

| I01D0030 | Idemitsu Eponex IM | NLGI 1 | 6 |

◆ Instruction of Replacing 700cc Grease Cartridge

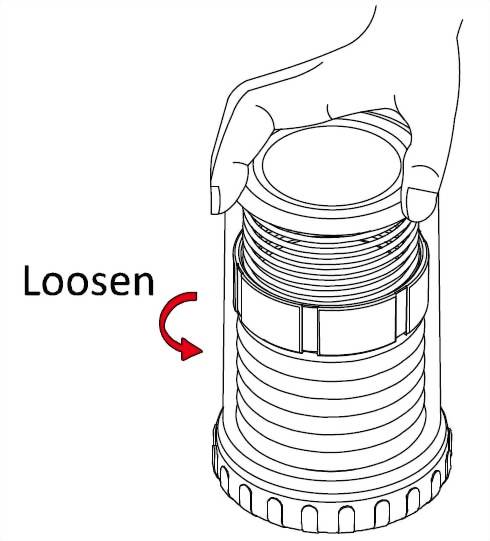

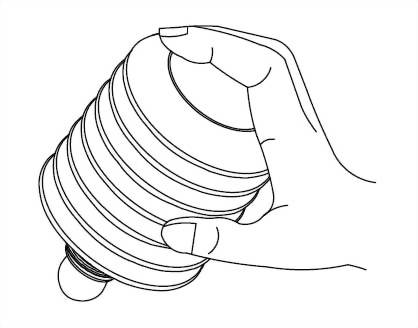

1

Hold the grease cartridge cover tightly and turn it anticlockwise

to disassemble it from the grease cartridge cover base .

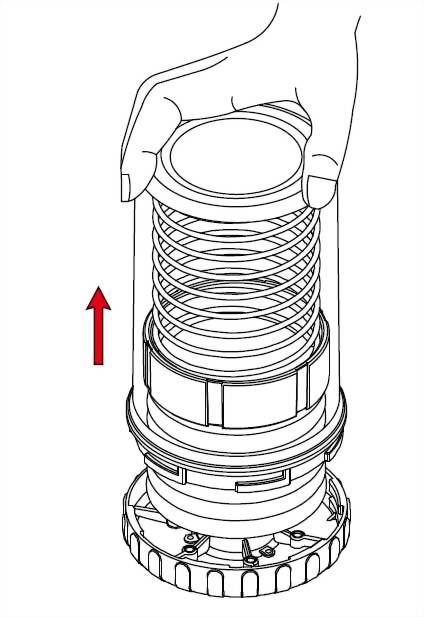

2

Take the grease cartridge cover out and put it aside.

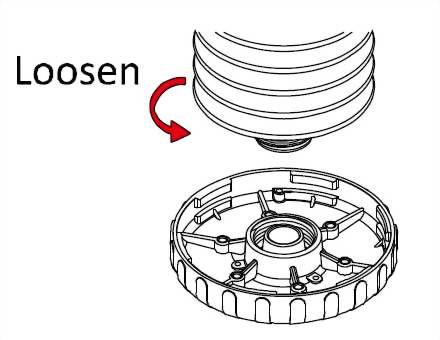

3

Rotate the used grease

cartridge anticlockwise to remove it from the grease cartridge cover base and dispose of it

properly.

4

Before replacing a new grease cartridge, lightly squeeze out a

little grease in the grease cartridge to prevent air from entering the

lubricator.

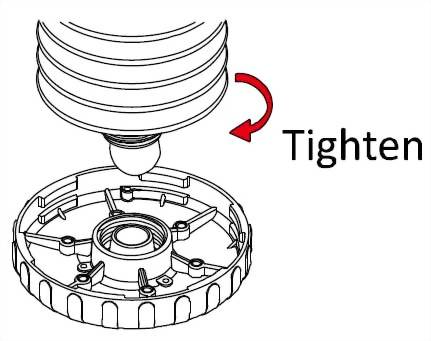

5

Assemble the new grease cartridge to the grease cartridge cover base by turning it clockwise.

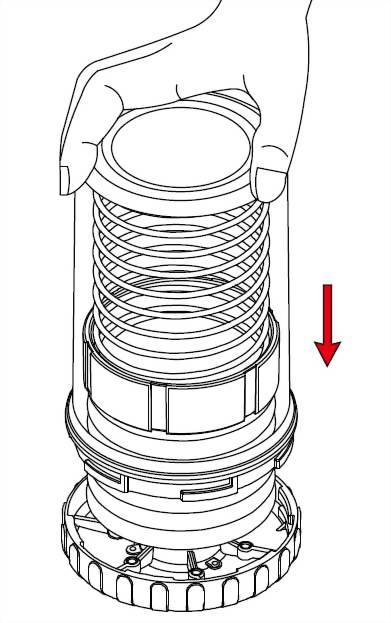

6

Assemble the grease cartridge cover back to the grease cartridge cover base.

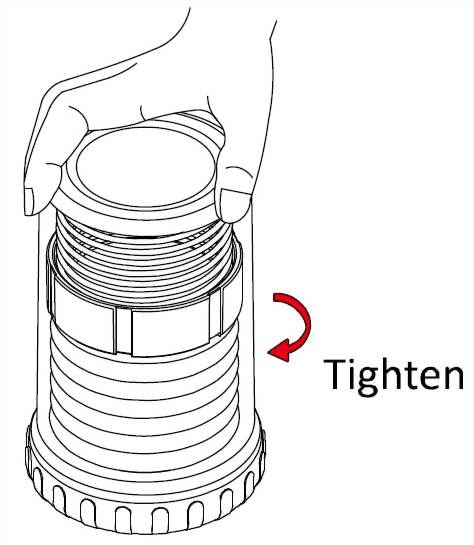

7

Rotate the grease cartridge cover clockwise to assemble it with the grease cartridge cover base to complete the replacement of the grease cartridge.